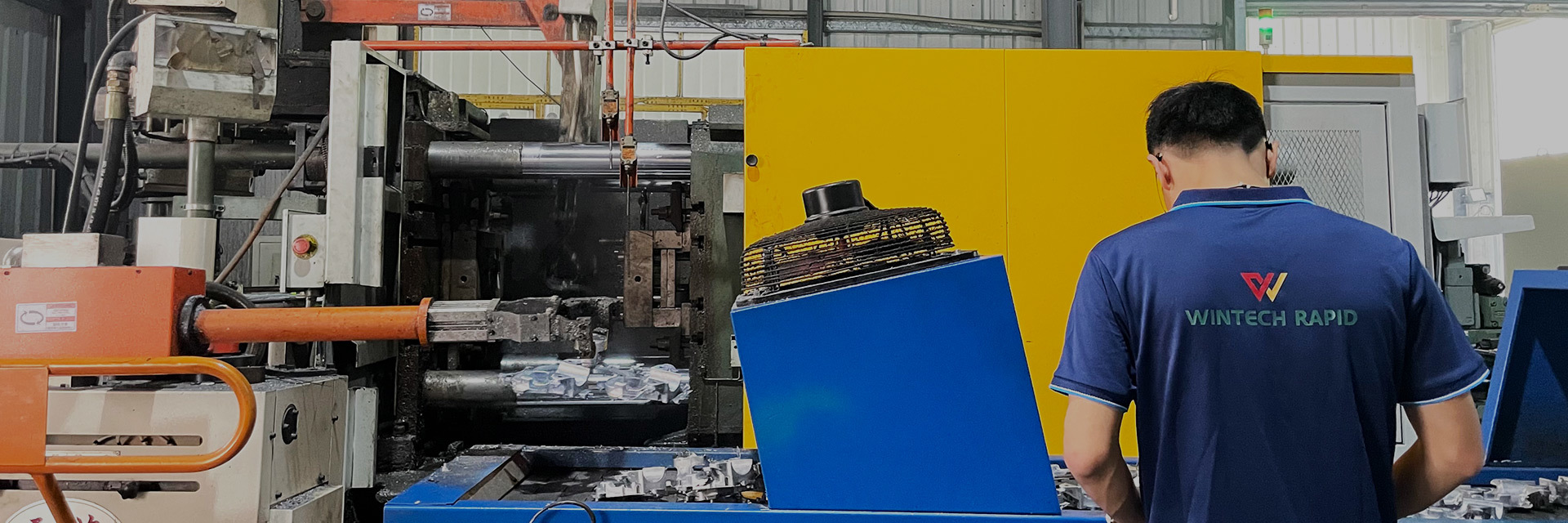

Die Casting

ADC10/12, A380, Zinc 3#/5# and Magnesium Make tens of thousands of parts economically Complex geometries can be achieved

Die Casting

What is pressure die casting ?

Pressure die casting is an ideal method for making large quantities of metal parts with excellent surface finish and dimensional stability.

Wintech Rapid can produce complex, high quality aluminum (ADC10/12 and A380 typically) and zinc (3#/5#) die castings for a wide range of industries.

And we have the capability to machine, finish and assemble our castings to meet even the most challenging design requirements. The finishing including powder coating, spray painting, anodizing, polishing and plating.

We pride ourselves in using our experience and technology to produce castings with complex geometries and stringent porosity requirements using a wide range of casting alloys. Our capability and experience allows us to achieve our ultimate goal: Providing the best possible products and service to our customers.

Part quantities may vary from 50 or 100 off prototype parts to many thousands of mass production requirements-all of which will be produced with the care and precision we apply to all our projects. Please feel free to contact us for a free quote.

Why use Wintech for Metal Casting?

● We have built up an excellent relationship with our partners for pressure die casting and investment casting.

● We have a huge amount of precision CNC machines for post-machining

● With our project management experience, we can guarantee a smooth transfer of information and punctual delivery.

Advantages of Pressure Die Casting

Compared with other processes, die-casting has significant advantages in cost savings, especially for some structurally complex parts. It includes the following other advantages:

● Excellent dimensional accuracy

● Directly casting high-strength parts within the structure

● Good surface finish compared to other processesReduce material waste

● Long lifespan - basically thousands of parts can be made from a single mold before replacement

If you need to inquire about our products or price list, please leave your email to us

rapid prototyping tooling | rapid tooling prototyping company | rapid prototype tooling | aluminium rapid prototyping | rapid prototyping aluminium | rapid injection molding prototy yping | rapid injection molding prototypes | rapid silicone prototyping | silicone rapid prototyping | rapid prototype silicone parts | rapid prototyping abs plastic | vacuum casting china| rapid prototype rubber | rapid prototyping rubber | rapid prototype rubber parts |rapid prototyping silicone rubber parts | rapid prototyping rubber molding | rapid prototyping wood | small series plastic cnc machining | china precision cnc machining factory | rapid tooling rapid prototyping

CNC Milling Service China|CNC Machining China|3D | Injection Mold China | Silicone Molding China| Small Batch Injection Molding| Die Casting Mould |Low Volume Production | Rapid Tooling | Rapid Aluminium |Silicone Compression Molding |

|Small Batch CNC Machinig | Online Injection Molding | Rapid Injection Molding |Plastic Mouldings | Rapid Prototypes | Injection Molding Tool |CNC Machining Supplier | Sheet Metal Prototy types|Injection Moulding |CNC Machining |cnc machining in china | china cnc machining | cnc machining services china | china precision cnc machining parts | china aerospace cnc machining factory | china cnc machining metal parts|china cnc machining plastic parts |china cnc machining service suppliers | china sheet me etal bending | china cnc machining parts | china cnc machining suppliers | china plastic cnc machining l china cnc machining part | china cnc machining manufacturer | plastic cnc mach ining china | china precision cnc machining suppliers |cnc machining parts china | china cnc machining parts manufacturer | precision cnc machining china | cnc machining china factorry | cnc machining companies in china | china stainless steel cnc machining supplier | rapid sheet metal prototype | rapid sheet metal prototyping | sheet metal prototype service| shee et metal china | rapid steel prototyping | china sheet metal bending parts | rapid prototype sheet metal| rapid prototyping sheet metal | sheet metal rapid prototyping | sheet metal proto totype | 3d print service china|3d printing service china | china 3d printing service |3d printing services china | 3d printing parts china | chinese 3d printing servic| sla rapid prototyping services| cnc machining service china | china cnc machining centre | china cnc machining factory