How Injection Parts Work Together for Optimal Results in Plastic Molding

Time:

2025-06-16 09:00

Source:

How Injection Parts Work Together for Optimal Results in Plastic Molding

Table of Contents

- Understanding Injection Molding

- Key Components of Injection Molding

- The Injection Molding Process Explained

- The Role of Injection Parts in the Process

- Collaboration of Injection Parts for Efficiency

- Optimizing Injection Molding for Better Results

- Common Challenges in Injection Molding

- Future Trends in Injection Molding Technology

- Frequently Asked Questions

Understanding Injection Molding

Injection molding is a widely used manufacturing process for creating parts by injecting molten material into a mold. This method is prevalent in the production of plastic components and offers several advantages, including high efficiency, repeatability, and the ability to create complex shapes. Understanding how injection parts interact is crucial for achieving optimal results in this industry.

What is Injection Molding?

At its core, injection molding involves several key steps: melting the raw material, injecting it into a mold, and allowing it to cool and solidify. This process can produce anything from small components to large structural parts, making it a versatile solution for many applications.

Benefits of Injection Molding

The benefits of injection molding extend beyond mere production speed. Some advantages include:

- **High precision**: The process allows for tight tolerances and complex geometries.

- **Material efficiency**: Minimal waste is produced during the molding process.

- **Scalability**: It is suitable for both small and large production runs.

Key Components of Injection Molding

To fully appreciate how injection parts work together, it is essential to understand the primary components of the injection molding system. These parts play distinct roles in ensuring the efficiency and quality of the final product.

The Injection Unit

The injection unit is responsible for heating and injecting the molten material into the mold. It consists of several key components:

- **Hopper**: Holds the raw material before it is fed into the barrel.

- **Barrel**: Heats the material until it reaches a molten state.

- **Screw**: Moves the molten material toward the nozzle and into the mold.

The Clamping Unit

The clamping unit secures the mold during the injection process. It ensures that the mold remains closed under pressure while the material is injected. The components of the clamping unit include:

- **Platens**: Provide the framework for the mold.

- **Clamp**: Applies the necessary force to hold the mold closed.

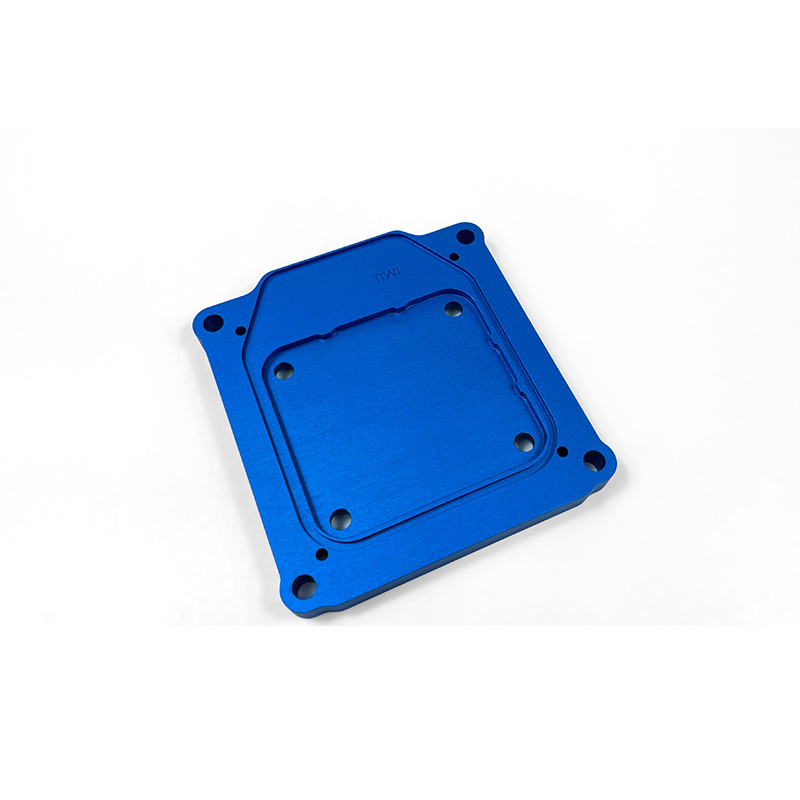

- **Mold**: The cavity into which the molten material is injected.

Cooling System

Once the molten material is injected, it needs to cool and solidify. The cooling system typically includes:

- **Cooling channels**: Circulate a coolant to lower the temperature of the mold.

- **Thermocouples**: Monitor the temperature of the mold to ensure effective cooling.

The Injection Molding Process Explained

To understand how injection parts work together, it is essential to break down the injection molding process into its constituent steps.

Step 1: Material Preparation

The first step involves preparing the raw material, typically in the form of granules. These granules are placed into the hopper of the injection unit.

Step 2: Melting the Material

As the screw rotates, it feeds the granules into the heated barrel. The controlled heat melts the material, transforming it into a viscous liquid.

Step 3: Injection

Once the material reaches the desired temperature, it is injected into the mold under high pressure. This step is crucial as it determines the fill rate and ensures that the mold cavity is completely filled.

Step 4: Cooling

After injection, the cooling system activates. The cooling channels circulate coolant, allowing the material to solidify as it cools down. This step is vital for achieving the desired part characteristics.

Step 5: Ejection

Once the part has cooled and solidified, the clamping unit retracts, and the mold opens. Ejector pins push the finished part out of the mold.

The Role of Injection Parts in the Process

Each part of the injection molding machine plays an integral role in ensuring the overall efficiency and quality of the manufacturing process. Understanding these roles can help in diagnosing issues and optimizing performance.

The Injection Unit's Contribution

The injection unit is critical for maintaining the correct temperature and pressure during the injection process. Any discrepancies can lead to defects in the final product.

The Clamping Unit's Importance

The clamping unit must apply sufficient force to withstand the pressure of the injected material. An inadequate clamping force can result in flash or incomplete parts.

Cooling System Efficiency

Proper cooling is essential for maintaining cycle times and ensuring part quality. An inefficient cooling system can lead to warping or incomplete solidification.

Collaboration of Injection Parts for Efficiency

To achieve optimal results, the various injection parts must work together harmoniously. This collaboration is key to maximizing efficiency and minimizing defects.

Synchronization of Processes

Synchronization between the injection and clamping units is essential. The timing of the injection and cooling processes must align to ensure that the mold is filled correctly before cooling begins.

Material Flow Management

Managing the flow of material throughout the injection unit is crucial. Adjusting the screw speed and temperature can optimize the flow and fill the mold evenly.

Optimizing Injection Molding for Better Results

Achieving optimal results in injection molding requires a careful balance of various factors. Here are strategies for optimizing the process.

Choosing the Right Material

Selecting the appropriate material for the application is vital. Factors such as temperature resistance, strength, and flexibility should be considered when choosing the material.

Fine-Tuning Machine Settings

Adjusting machine parameters such as injection speed, temperature, and pressure can significantly impact the final product quality. Experimenting with these settings can lead to better results.

Regular Maintenance

Frequent maintenance of the injection molding equipment is essential for preventing breakdowns and ensuring consistent performance. Regularly checking and calibrating components can extend the lifespan of the machinery.

Common Challenges in Injection Molding

Despite its advantages, injection molding does face certain challenges that can impact productivity and quality.

Defects in Finished Products

Common defects include short shots, sink marks, and warping. Identifying the root causes of these defects is crucial for implementing corrective measures.

Cycle Time Optimization

Long cycle times can reduce productivity. Optimizing each step of the process, from injection to cooling, can help to minimize cycle time without sacrificing quality.

Future Trends in Injection Molding Technology

As technology evolves, so too does the injection molding process. Numerous trends are shaping the future of this industry.

Advancements in Materials

Innovations in material science are leading to the development of new polymers that offer enhanced properties and performance characteristics.

Automation and Smart Technology

The integration of smart technology and automation is revolutionizing injection molding, allowing for real-time monitoring and adjustments to the manufacturing process.

Sustainability Initiatives

As environmental concerns grow, the injection molding industry is moving towards more sustainable practices, including the use of biodegradable materials and energy-efficient machinery.

Frequently Asked Questions

What is the typical cycle time for injection molding?

The cycle time can vary based on part size and complexity but usually ranges from 15 to 120 seconds.

How can I prevent defects in injection molded parts?

Regular maintenance, optimizing machine settings, and selecting the right material are key strategies to reduce defects.

What materials are commonly used in injection molding?

Common materials include ABS, polypropylene, polycarbonate, and nylon, each chosen for specific properties.

How does the cooling process impact the final product?

The cooling process affects the dimensional stability and mechanical properties of the molded part; inadequate cooling can lead to defects.

What are the benefits of using automation in injection molding?

Automation increases efficiency, reduces labor costs, and enhances product consistency by minimizing human error.

Conclusion

Understanding how injection parts work together is fundamental to achieving optimal results in the injection molding process. By familiarizing ourselves with the components, their functions, and the collaborative efforts required, we can enhance productivity and produce high-quality plastic parts. With ongoing advancements in technology and materials, the future of injection molding looks promising, paving the way for more efficient and sustainable manufacturing practices. Embracing these developments will be crucial for businesses aiming to stay competitive in the evolving landscape of plastic manufacturing.

parts of the injection

Previous Page

Previous Page

Related news

2024-11-15