Understanding the Factors That Influence Plastic Molding Cost: A Comprehensive Guide

Time:

2025-07-22 16:20

Source:

Understanding the Factors That Influence Plastic Molding Cost

Introduction to Plastic Molding Cost

Plastic molding is a crucial process in manufacturing that transforms raw plastic into finished products. Given its widespread applications across various industries, understanding the factors influencing plastic molding cost is essential for businesses aiming to optimize their production budgets. This comprehensive guide will illuminate the various elements that can significantly affect the overall expenses associated with this manufacturing technique.

Table of Contents

- 1. Overview of Plastic Molding

- 2. Key Factors Affecting Plastic Molding Costs

- 2.1. Material Choices

- 2.2. Mold Design and Complexity

- 2.3. Production Volume

- 2.4. Lead Time Considerations

- 3. The Role of Labor Costs

- 4. Maintenance and Upkeep of Molds

- 5. Quality Control and Testing

- 6. Innovations Impacting Costs

- 7. Tips for Reducing Plastic Molding Costs

- 8. FAQs About Plastic Molding Costs

- 9. Conclusion: Balancing Cost and Quality in Plastic Molding

1. Overview of Plastic Molding

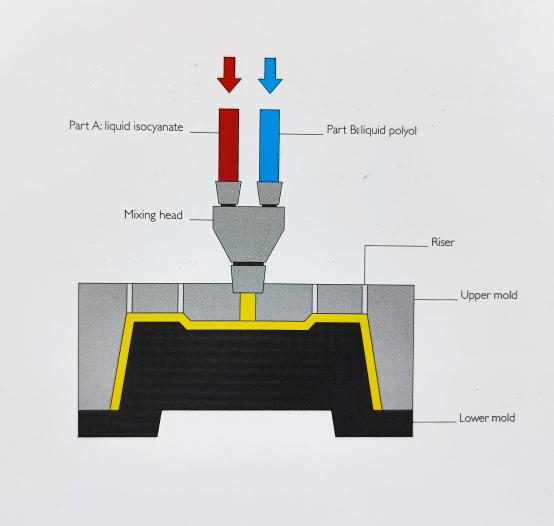

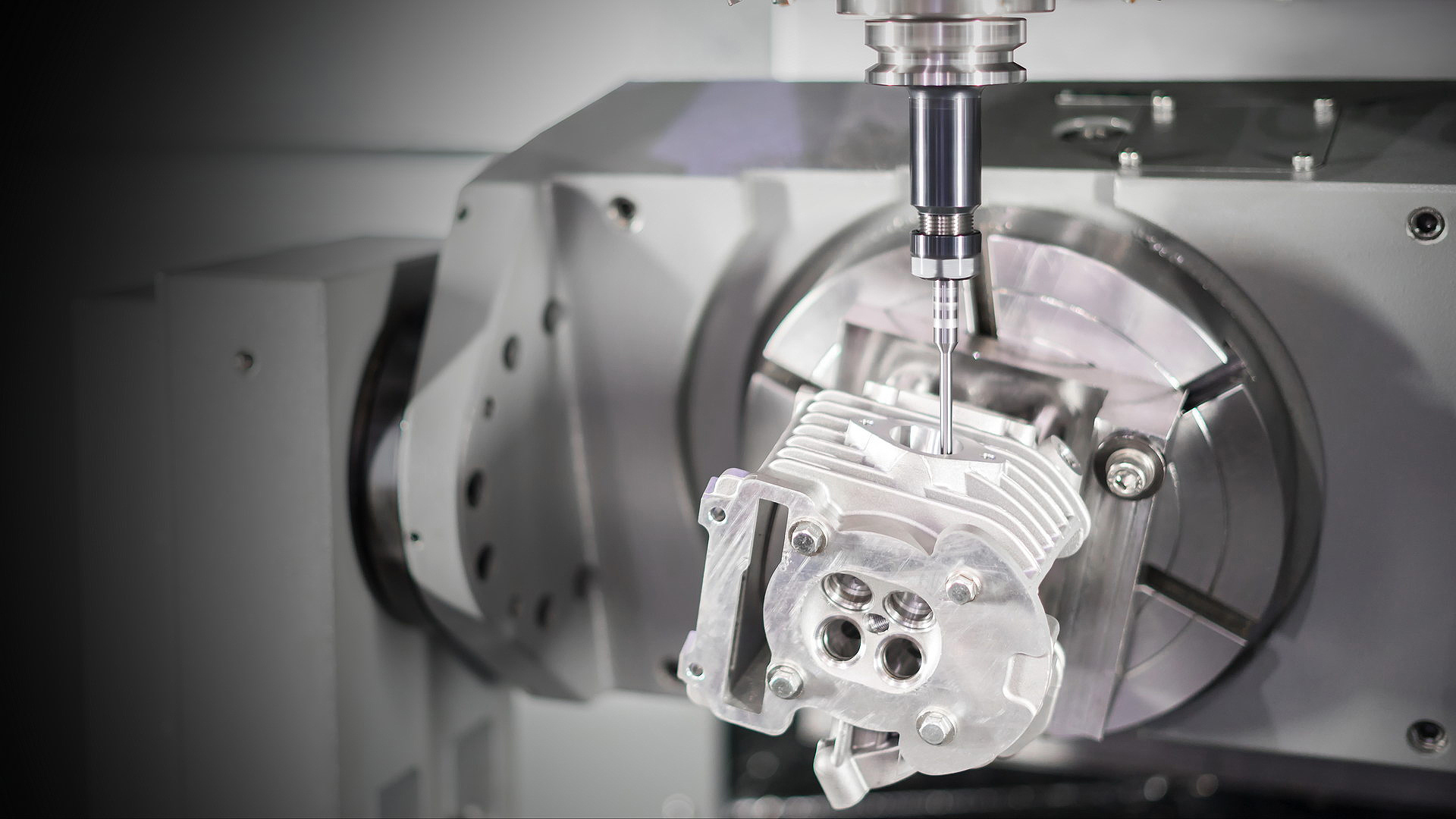

Plastic molding encompasses various techniques used to create plastic parts and products. Common methods include injection molding, blow molding, and rotational molding. Each technique has its unique advantages, but they all share a common end goal: cost-effective, high-quality production. Understanding the intricacies of plastic molding is vital for companies looking to innovate while managing their production costs effectively.

2. Key Factors Affecting Plastic Molding Costs

Numerous factors influence the overall cost of plastic molding. Understanding these elements can help businesses make informed decisions to enhance profitability while maintaining product quality.

2.1. Material Choices

The choice of materials directly impacts the cost of plastic molding. Various plastics, such as polycarbonate, polypropylene, and ABS, come with different price tags, properties, and processing requirements. **Higher quality materials may yield better performance** but can also increase costs significantly. Evaluating material options based on the intended use, durability requirements, and budget constraints is crucial for cost-effective production.

2.2. Mold Design and Complexity

The design of the mold is another pivotal factor in determining costs. **Complex mold designs** require more time and expertise to create, leading to higher initial costs. Features such as undercuts, draft angles, and intricate geometries add complexity and can complicate the molding process. Investing in a well-thought-out mold design can lead to better manufacturing efficiency and lower costs in the long run, as it can reduce cycle times and improve part quality.

2.3. Production Volume

Production volume significantly affects the overall cost-per-unit in plastic molding. Higher production runs typically result in lower costs per unit due to the amortization of mold costs over a larger number of parts. Conversely, small production runs can lead to higher unit costs as the initial setup and mold costs must be absorbed by fewer products. Finding the right balance between production volume and cost-effectiveness is essential for maintaining profitability.

2.4. Lead Time Considerations

Lead time is a critical aspect of production that can influence costs. **Shorter lead times often require expedited processes**, which can increase costs significantly. Companies must balance the need for rapid delivery with the associated costs. Planning ahead and optimizing production schedules can help mitigate the impact of lead times on overall costs.

3. The Role of Labor Costs

Labor costs play a significant role in the overall cost of plastic molding. Skilled labor is often required to operate machinery, supervise production, and ensure quality control. Additionally, labor costs can vary based on geographical location, the complexity of the task, and the level of expertise required. Investing in training and workforce development can improve efficiency and reduce errors, ultimately lowering production costs.

4. Maintenance and Upkeep of Molds

Proper maintenance and upkeep of molds are essential for cost-effective production. Well-maintained molds can enhance productivity and reduce the likelihood of defects. **Regular inspections and timely repairs** can prolong the life of molds, spreading out the initial investment over a larger number of products. Companies should establish a maintenance schedule to ensure molds remain in optimal condition.

5. Quality Control and Testing

Quality control is an integral part of the plastic molding process that can influence costs. Ensuring that products meet necessary specifications often requires additional testing and inspections, which can add to the overall costs. However, investing in quality control can prevent costly defects and recalls, leading to long-term savings. Implementing effective quality assurance procedures can enhance customer satisfaction and loyalty.

6. Innovations Impacting Costs

Technological advancements in plastic molding are continually evolving, impacting production costs. Innovations such as automation, advanced materials, and improved machinery can lead to more efficient processes. Companies that stay abreast of these developments and invest in new technologies may find opportunities to reduce costs while enhancing product quality.

7. Tips for Reducing Plastic Molding Costs

To maintain competitiveness, businesses must actively seek ways to reduce plastic molding costs without compromising quality. Here are several strategies:

- **Optimize Material Selection**: Evaluate the performance requirements and costs of various materials to find the best fit for your needs.

- **Invest in Efficient Mold Design**: Focus on creating molds that reduce cycle times and enhance productivity.

- **Increase Production Volume**: Determine the right balance between production volume and overall costs to take advantage of economies of scale.

- **Implement Lean Manufacturing Principles**: Streamline processes and eliminate waste to improve efficiency and reduce costs.

- **Leverage Technology**: Explore automation and advanced manufacturing techniques to enhance productivity and reduce labor costs.

8. FAQs About Plastic Molding Costs

What factors contribute to the cost of plastic molding?

Several factors contribute to plastic molding costs, including material selection, mold complexity, production volume, labor expenses, and lead time considerations.

How can I reduce the costs associated with plastic molding?

Businesses can reduce costs by optimizing material choices, improving mold designs, increasing production volumes, and adopting lean manufacturing principles.

Is it better to invest in high-quality materials for molding?

High-quality materials can offer better performance and durability, which may justify their higher costs in the long run, especially for products requiring specific performance standards.

How does production volume affect per-unit costs?

Higher production volumes typically decrease per-unit costs as the fixed costs of mold creation and setup are spread over more units.

What role does quality control play in molding costs?

Quality control can add to production costs but is essential for preventing defects and maintaining customer satisfaction. Investing in quality assurance can lead to long-term savings.

9. Conclusion: Balancing Cost and Quality in Plastic Molding

Navigating the complexities of plastic molding costs requires a comprehensive understanding of the various factors at play. From material selection to mold design and production volume, every element plays a crucial role in determining overall expenses. By leveraging strategies to optimize these factors, businesses can achieve a balance between cost efficiency and product quality. Embracing innovation and investing in advanced technologies can further enhance competitiveness in this dynamic industry. As you explore your options, remember that a thoughtful approach to plastic molding can lead to significant long-term benefits and success in your manufacturing endeavors.

plastic molding cost

Previous Page

Previous Page

Related news

2024-11-15