Innovative Applications of Rapid Plastic Injection Molding in Consumer Goods

Time:

2025-05-14 09:20

Source:

Innovative Applications of Rapid Plastic Injection Molding in Consumer Goods

Table of Contents

- Introduction to Rapid Plastic Injection Molding

- What is Rapid Plastic Injection Molding?

- Advantages of Rapid Plastic Injection Molding in Consumer Goods

- Key Applications in Consumer Goods

- Food Packaging Solutions

- Innovative Toys and Games

- Molding for Electronics

- Designing Household Products

- Case Studies: Successful Implementations

- Environmental Impact of Rapid Injection Molding

- Future Trends in Rapid Plastic Injection Molding

- Frequently Asked Questions

- Conclusion

Introduction to Rapid Plastic Injection Molding

The landscape of consumer goods is constantly evolving. **Rapid plastic injection molding** has emerged as a vital technology, enabling manufacturers to respond quickly to market demands while maintaining quality and reducing costs. This technique allows for the swift production of complex plastic parts, making it a perfect fit for the fast-paced consumer goods industry.

What is Rapid Plastic Injection Molding?

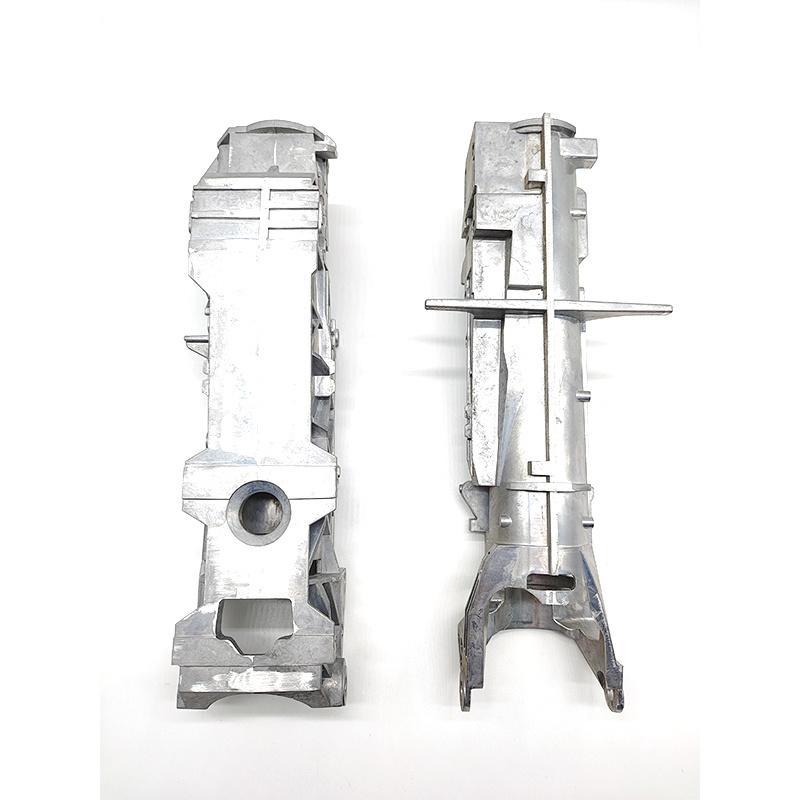

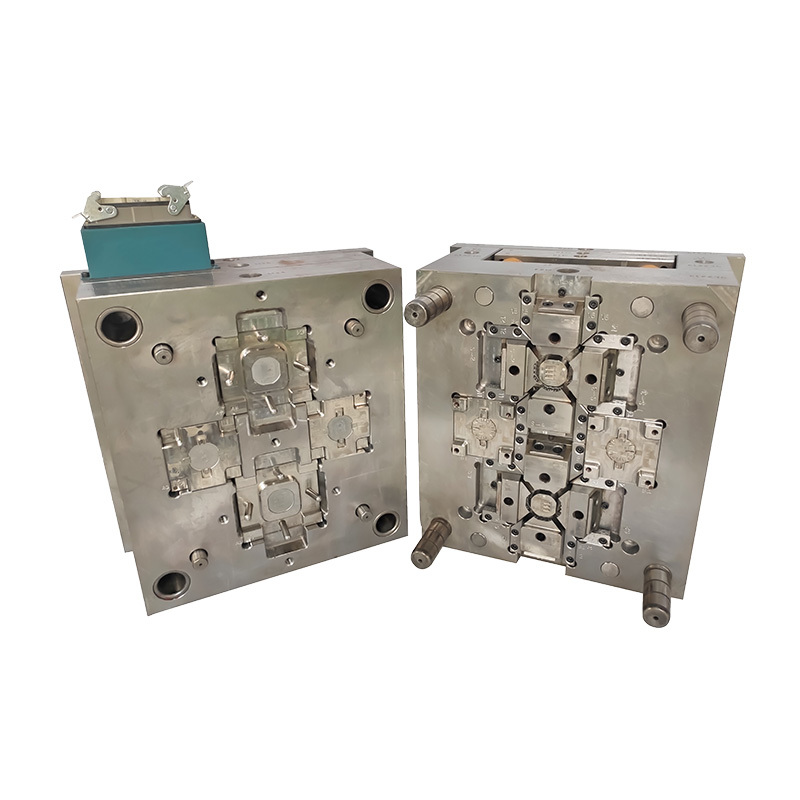

**Rapid plastic injection molding** refers to a manufacturing process that combines speed and efficiency to produce plastic parts in large quantities. Unlike traditional methods, which can be time-consuming and costly, rapid molding utilizes advanced technologies and materials to create high-quality products in a fraction of the time. This process is particularly beneficial for prototyping, product testing, and small to medium production runs, ensuring that businesses can introduce new products to the market swiftly.

Advantages of Rapid Plastic Injection Molding in Consumer Goods

The benefits of utilizing rapid plastic injection molding in the production of consumer goods are extensive:

1. Speed to Market

One of the primary advantages is the **reduced time to market**. Companies can develop prototypes and begin production much faster than with traditional methods, allowing them to capitalize on emerging trends and consumer demands.

2. Cost-Effectiveness

Rapid molding reduces costs by minimizing waste and optimizing material usage. The efficiency of the molding process means that manufacturers can produce high volumes at lower costs, translating into significant savings.

3. Design Flexibility

With rapid molding, designers have the freedom to explore innovative shapes and features without the constraints imposed by traditional manufacturing methods. This enhances creativity and leads to unique product offerings.

4. High Precision and Quality

Modern rapid plastic injection molding techniques deliver **precise and consistent** results, ensuring that each product meets stringent quality standards. This reliability is crucial in maintaining brand reputation in competitive markets.

5. Sustainability

By optimizing the use of materials and reducing energy consumption, rapid molding processes are often more sustainable than traditional methods. This contributes to the growing demand for environmentally friendly manufacturing solutions.

Key Applications in Consumer Goods

Rapid plastic injection molding has found a wide array of applications in the consumer goods sector. Here are some notable examples:

Food Packaging Solutions

The food industry has embraced rapid molding for creating innovative and sustainable packaging solutions. **Custom containers, lids, and sealing mechanisms** can be produced quickly to meet the specific needs of food safety and preservation.

Innovative Toys and Games

Children's toys often require colorful, durable components that can be produced rapidly. Rapid molding allows manufacturers to create intricate designs that attract children's attention while ensuring safety and compliance with industry standards.

Molding for Electronics

In the electronics sector, rapid molding is used for producing **enclosures, casings, and components** that require high precision. The lightweight nature of molded plastics combined with their durability makes them ideal for various electronic devices.

Designing Household Products

From kitchen gadgets to furniture fittings, rapid plastic injection molding facilitates the creation of stylish and functional household items. The ability to customize designs quickly allows companies to cater to diverse consumer preferences.

Case Studies: Successful Implementations

Several companies have successfully implemented rapid plastic injection molding in their production processes, leading to impressive results:

Case Study 1: A Leading Toy Manufacturer

A major toy manufacturer adopted rapid molding to streamline its production line, significantly reducing the time taken to launch new products. By utilizing this technology, they reported a 30% reduction in costs and an increase in market responsiveness.

Case Study 2: Innovative Electronics Brand

An electronics brand turned to rapid plastic injection molding to develop a line of customizable phone cases. The company was able to introduce multiple designs within a short timeframe, leading to a substantial increase in sales and customer engagement.

Environmental Impact of Rapid Injection Molding

Sustainability is becoming increasingly important in manufacturing practices. Rapid plastic injection molding can be a more sustainable choice compared to traditional methods. By reducing material waste and energy consumption, companies can minimize their environmental footprint. Additionally, many manufacturers are exploring the use of biodegradable and recycled materials in their molding processes, further enhancing their commitment to sustainability.

Future Trends in Rapid Plastic Injection Molding

As technology continues to evolve, so does the field of rapid plastic injection molding. Here are some trends to watch for:

1. Integration of AI and Automation

The integration of artificial intelligence and automation in rapid molding processes is set to enhance efficiency and precision. Smart machines can predict maintenance needs, optimize production schedules, and reduce downtime.

2. Advancements in Materials

The development of new materials, including advanced composites and environmentally friendly alternatives, will further expand the capabilities of rapid plastic injection molding, allowing for lighter, stronger, and more sustainable products.

3. Customization and Personalization

As consumer preferences shift toward personalized products, rapid molding will enable manufacturers to offer customization at scale, enhancing customer satisfaction and loyalty.

4. Enhanced Collaboration

The growth of collaborative platforms will facilitate better communication between designers, engineers, and manufacturers, streamlining the product development process and fostering innovation.

Frequently Asked Questions

1. What industries benefit from rapid plastic injection molding?

Rapid plastic injection molding is used across various industries, including consumer goods, automotive, electronics, and healthcare, due to its versatility and efficiency.

2. How does rapid molding reduce costs?

It reduces costs by minimizing waste, optimizing material usage, and decreasing production times, allowing manufacturers to produce more at lower prices.

3. Can rapid plastic injection molding handle complex designs?

Yes, one of the main advantages of this technology is its ability to produce intricate and complex designs that may be challenging for traditional manufacturing methods.

4. Is rapid molding environmentally friendly?

When implemented thoughtfully, rapid molding can be more sustainable due to reduced waste and energy consumption, and many companies are now using recycled materials.

5. What are the future prospects for rapid plastic injection molding?

The future of rapid plastic injection molding looks promising, with advancements in technology, materials, and sustainable practices expected to drive growth and innovation in the coming years.

Conclusion

The innovative applications of rapid plastic injection molding are transforming the consumer goods landscape by enhancing efficiency, reducing costs, and enabling creative design possibilities. As technology advances, we can expect this manufacturing process to play an even more significant role in shaping the future of consumer products. By embracing these innovations, manufacturers can meet consumer demands and stay competitive in an ever-evolving market.

rapid plastic injection molding

Related news

2024-11-15