Unlocking the Benefits of Fast Injection Molding in Precision Manufacturing

Time:

2025-05-17 09:40

Source:

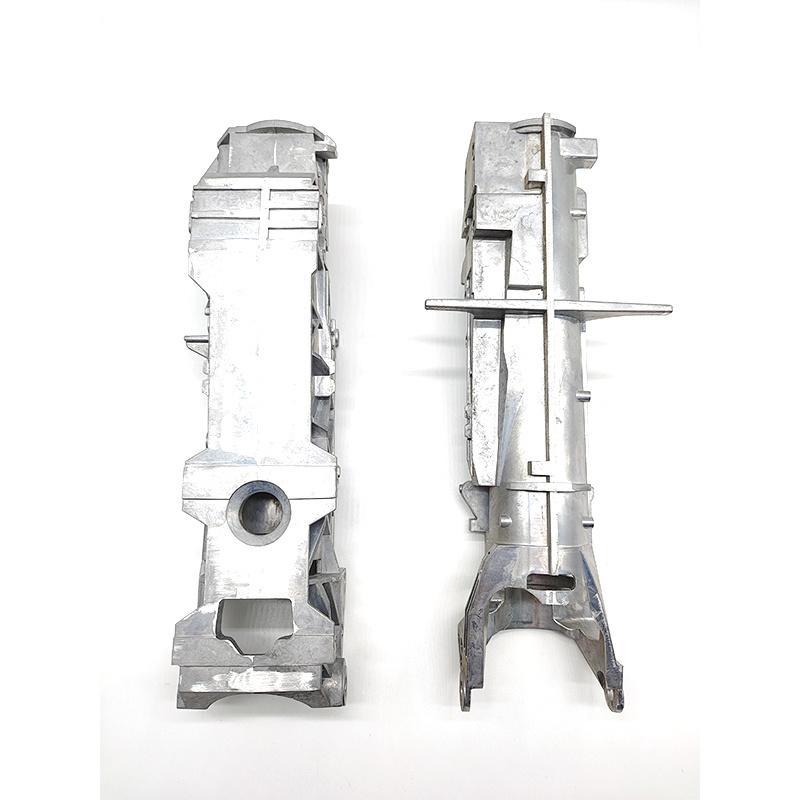

Fast injection molding is an advanced technique in the realm of manufacturing that enhances the efficiency of producing plastic parts. This process is particularly valuable in the mechanical hardware processing and mold-making industries, where precision and speed are crucial. By utilizing fast injection molding, manufacturers can significantly reduce cycle times, thus increasing production rates and enabling quicker response to market demands.

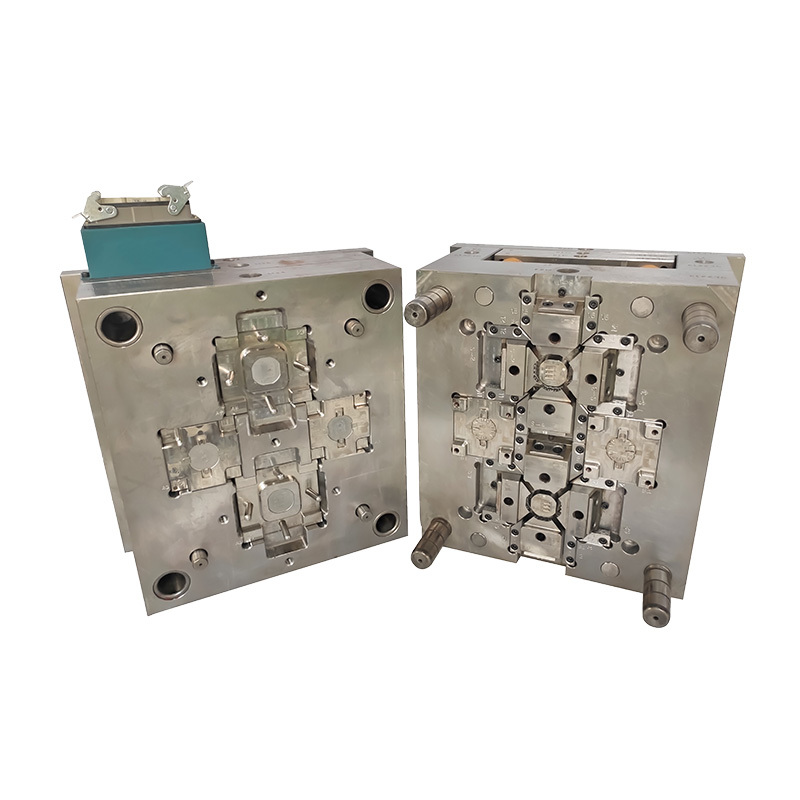

At its core, fast injection molding optimizes the traditional injection molding process. It employs advanced technologies, such as high-speed injection machines and optimized mold designs, to shorten the time it takes to create high-quality components. This method allows for the rapid production of intricate designs and complex geometries often required in various applications, from automotive to consumer electronics.

One of the most notable advantages of fast injection molding is its ability to improve production efficiency. Traditional injection molding processes can be time-consuming, with lengthy cooling and cycle times. Fast injection molding addresses these challenges by minimizing these durations. For instance, innovative cooling systems and advanced temperature control techniques enable quicker cooling of the molded parts, thereby expediting the overall production cycle.

Moreover, fast injection molding helps in maintaining high-quality standards while boosting output. The precision of this technique ensures that the produced parts meet stringent specifications, reducing the likelihood of defects and the need for extensive post-production modifications. This reliability is particularly important in industries where tolerances are tight and product quality is paramount.

Another significant benefit of fast injection molding is its capacity for cost-effectiveness in large production runs. By reducing cycle times and waste, manufacturers can lower their operational costs while simultaneously meeting high-volume demands. This is especially relevant in a competitive market where time-to-market can be a decisive factor in a product's success.

Additionally, the versatility of fast injection molding allows for the use of a wide range of materials, including various types of plastics. This adaptability enables manufacturers to choose the right material for specific applications, enhancing functionality and performance.

In conclusion, fast injection molding is revolutionizing the manufacturing sector, providing a means to produce high-quality plastic components swiftly and efficiently. By adopting this innovative technique, businesses in the mechanical hardware processing and mold-making industries can improve their production capabilities, remain competitive, and better serve their customers. As the demand for rapid and precise manufacturing continues to grow, fast injection molding stands out as a crucial process that can meet these evolving needs.

At its core, fast injection molding optimizes the traditional injection molding process. It employs advanced technologies, such as high-speed injection machines and optimized mold designs, to shorten the time it takes to create high-quality components. This method allows for the rapid production of intricate designs and complex geometries often required in various applications, from automotive to consumer electronics.

One of the most notable advantages of fast injection molding is its ability to improve production efficiency. Traditional injection molding processes can be time-consuming, with lengthy cooling and cycle times. Fast injection molding addresses these challenges by minimizing these durations. For instance, innovative cooling systems and advanced temperature control techniques enable quicker cooling of the molded parts, thereby expediting the overall production cycle.

Moreover, fast injection molding helps in maintaining high-quality standards while boosting output. The precision of this technique ensures that the produced parts meet stringent specifications, reducing the likelihood of defects and the need for extensive post-production modifications. This reliability is particularly important in industries where tolerances are tight and product quality is paramount.

Another significant benefit of fast injection molding is its capacity for cost-effectiveness in large production runs. By reducing cycle times and waste, manufacturers can lower their operational costs while simultaneously meeting high-volume demands. This is especially relevant in a competitive market where time-to-market can be a decisive factor in a product's success.

Additionally, the versatility of fast injection molding allows for the use of a wide range of materials, including various types of plastics. This adaptability enables manufacturers to choose the right material for specific applications, enhancing functionality and performance.

In conclusion, fast injection molding is revolutionizing the manufacturing sector, providing a means to produce high-quality plastic components swiftly and efficiently. By adopting this innovative technique, businesses in the mechanical hardware processing and mold-making industries can improve their production capabilities, remain competitive, and better serve their customers. As the demand for rapid and precise manufacturing continues to grow, fast injection molding stands out as a crucial process that can meet these evolving needs.

fast injection molding

Previous Page

Previous Page

Related news

2024-11-15