Understanding Low Volume Plastic Parts: Benefits and Manufacturing Techniques

Time:

2025-07-27 14:40

Source:

In the realm of manufacturing, particularly in the machinery sector focused on molds and plastic forming, the production of low volume plastic parts has gained significant traction. Low volume production refers to the manufacturing of a limited quantity of parts, typically ranging from a few dozen to several thousand units. This approach is particularly beneficial for businesses that require specific, highly customized components without the need for large-scale production.

One of the primary advantages of low volume plastic parts is the flexibility they offer in design and material selection. Manufacturers can experiment with different polymers and fine-tune their designs based on client feedback or market demands. This adaptability is crucial in industries such as automotive, medical, and consumer products, where rapid prototyping and iterative design processes are often required. Furthermore, low volume production allows companies to introduce new products to market quickly, thus maintaining a competitive edge.

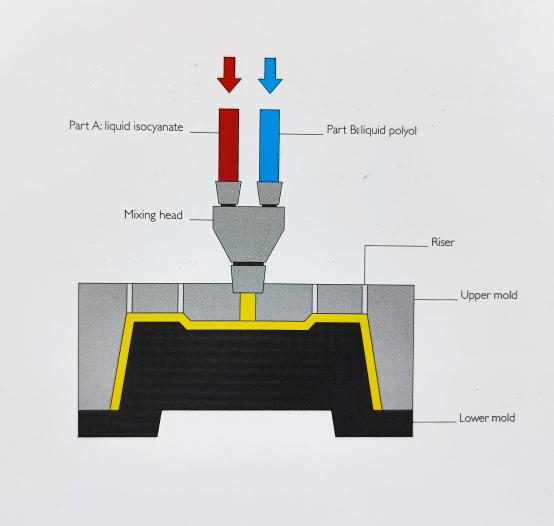

When it comes to manufacturing techniques, several methods are commonly employed for producing low volume plastic parts. One of the most widely used techniques is injection molding, which involves injecting molten plastic into a mold. While traditional injection molding can be expensive due to high initial setup costs, innovations such as 3D printing are changing the landscape. 3D printing enables the production of complex designs without the need for extensive tooling, making it a cost-effective solution for low volume runs.

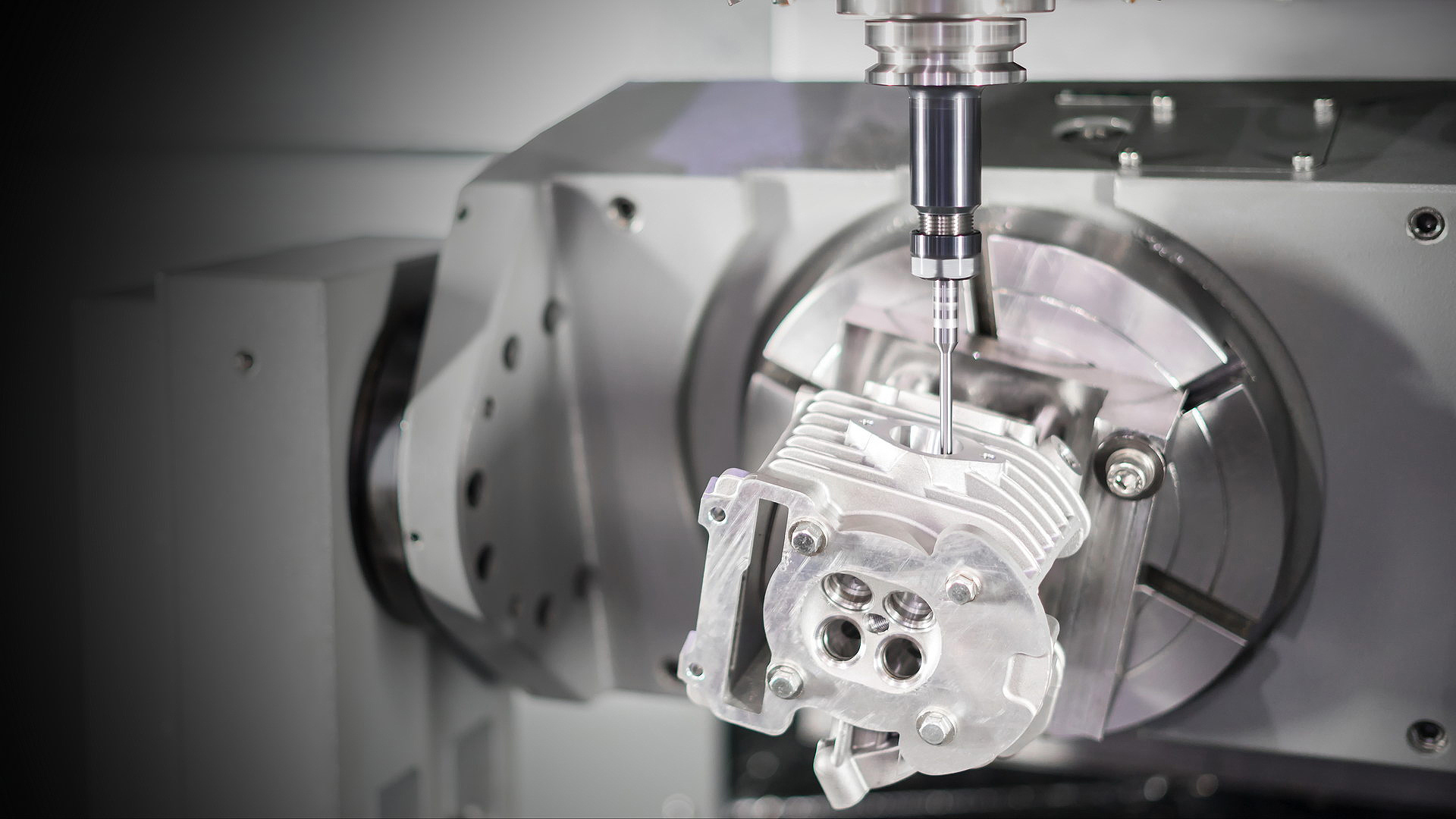

Another method gaining popularity is CNC machining. This technique allows for high precision and is particularly advantageous when working with high-performance plastics that may not be suitable for injection molding. CNC machining can produce parts with tight tolerances, making it ideal for applications where accuracy is paramount.

Additionally, low volume plastic parts can benefit from quick turnaround times. Using advanced manufacturing technologies and techniques, companies can reduce lead times significantly compared to traditional high volume production methods. This speed not only satisfies customer demands for timely delivery but also helps manufacturers manage inventory more efficiently.

Quality control is another vital aspect of producing low volume plastic parts. With fewer units being produced, manufacturers can implement stringent quality checks throughout the process. This focus on quality ensures that each part meets the desired specifications and performance standards, ultimately enhancing customer satisfaction.

In conclusion, low volume plastic parts play a critical role in modern manufacturing, particularly in sectors that require customization and rapid prototyping. By leveraging various manufacturing techniques and maintaining a strong focus on quality, businesses can effectively utilize low volume production to meet their specific needs while staying agile in a dynamic market.

One of the primary advantages of low volume plastic parts is the flexibility they offer in design and material selection. Manufacturers can experiment with different polymers and fine-tune their designs based on client feedback or market demands. This adaptability is crucial in industries such as automotive, medical, and consumer products, where rapid prototyping and iterative design processes are often required. Furthermore, low volume production allows companies to introduce new products to market quickly, thus maintaining a competitive edge.

When it comes to manufacturing techniques, several methods are commonly employed for producing low volume plastic parts. One of the most widely used techniques is injection molding, which involves injecting molten plastic into a mold. While traditional injection molding can be expensive due to high initial setup costs, innovations such as 3D printing are changing the landscape. 3D printing enables the production of complex designs without the need for extensive tooling, making it a cost-effective solution for low volume runs.

Another method gaining popularity is CNC machining. This technique allows for high precision and is particularly advantageous when working with high-performance plastics that may not be suitable for injection molding. CNC machining can produce parts with tight tolerances, making it ideal for applications where accuracy is paramount.

Additionally, low volume plastic parts can benefit from quick turnaround times. Using advanced manufacturing technologies and techniques, companies can reduce lead times significantly compared to traditional high volume production methods. This speed not only satisfies customer demands for timely delivery but also helps manufacturers manage inventory more efficiently.

Quality control is another vital aspect of producing low volume plastic parts. With fewer units being produced, manufacturers can implement stringent quality checks throughout the process. This focus on quality ensures that each part meets the desired specifications and performance standards, ultimately enhancing customer satisfaction.

In conclusion, low volume plastic parts play a critical role in modern manufacturing, particularly in sectors that require customization and rapid prototyping. By leveraging various manufacturing techniques and maintaining a strong focus on quality, businesses can effectively utilize low volume production to meet their specific needs while staying agile in a dynamic market.

low volume plastic parts

Previous Page

Previous Page

Related news

2024-11-15