Unlocking Efficiency: The Advantages of Rapid Tooling in Injection Molding

Time:

2025-09-12 15:02

Source:

Unlocking Efficiency: The Advantages of Rapid Tooling in Injection Molding

Table of Contents

- 1. Introduction to Rapid Tooling in Injection Molding

- 2. Understanding Rapid Tooling

- 3. Benefits of Rapid Tooling in Injection Molding

- 3.1 Cost-effectiveness of Rapid Tooling

- 3.2 Time Efficiency and Speed to Market

- 3.3 Design Flexibility and Iteration

- 3.4 Enhanced Production Quality

- 3.5 Sustainability Advantages

- 4. Implementing Rapid Tooling in Your Manufacturing Process

- 5. Case Studies: Successful Rapid Tooling Implementations

- 6. The Future of Rapid Tooling in Injection Molding

- 7. FAQs About Rapid Tooling in Injection Molding

- 8. Conclusion

1. Introduction to Rapid Tooling in Injection Molding

In today's fast-paced manufacturing landscape, **rapid tooling** has emerged as a pivotal technology in the injection molding industry. This innovative approach streamlines the tooling process, significantly enhancing efficiency and reducing costs. By leveraging advanced technologies, manufacturers can produce high-quality molds in a fraction of the time it traditionally takes, allowing for quicker product launches and improved market responsiveness.

2. Understanding Rapid Tooling

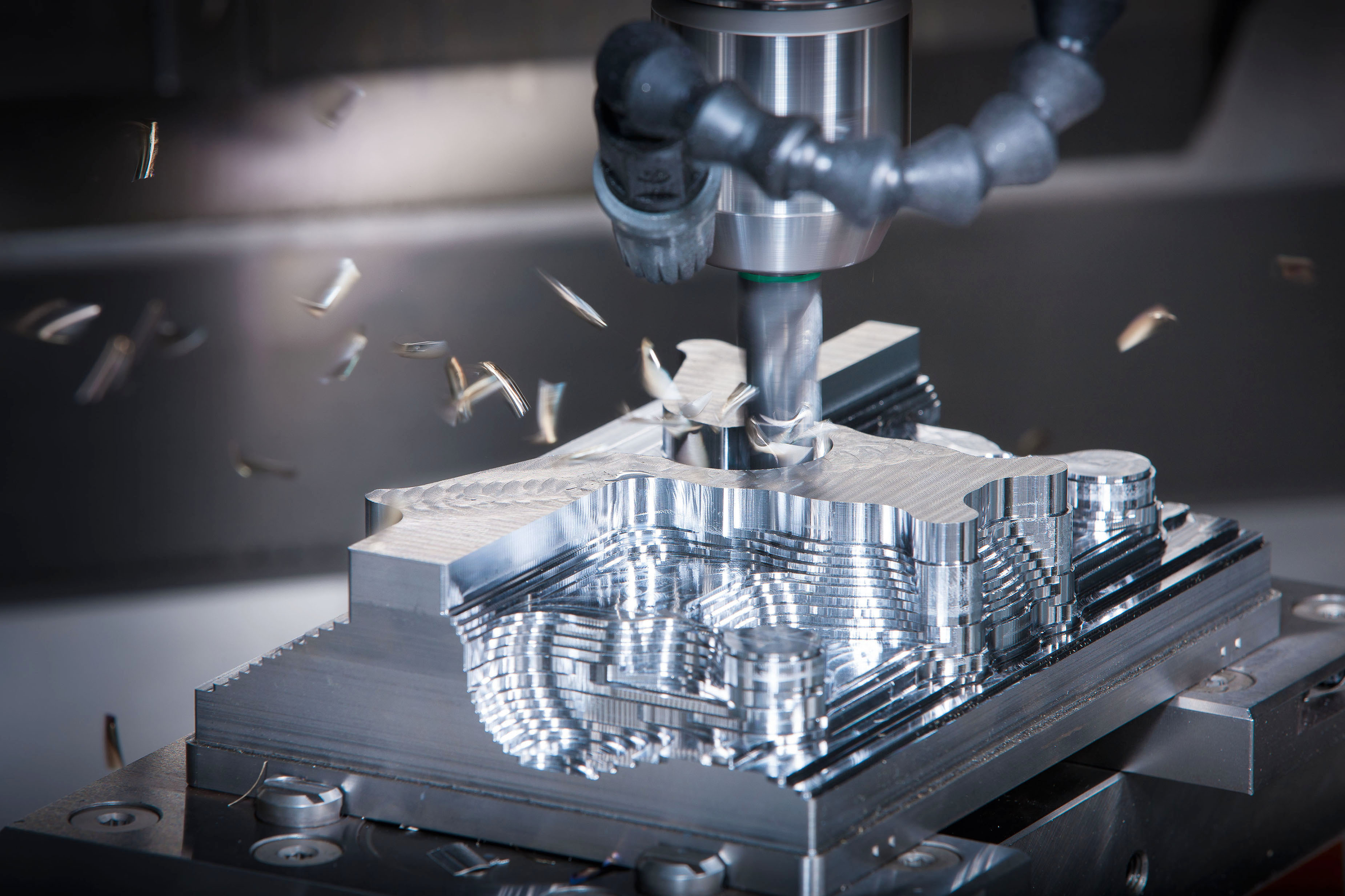

**Rapid tooling** refers to the accelerated production of molds used for injection molding. Unlike traditional methods, which often require extensive time and resources, rapid tooling employs modern techniques such as 3D printing, CNC machining, and other advanced manufacturing processes. This allows for the swift creation of complex mold designs, catering to the evolving needs of the market.

In essence, rapid tooling shortens the lead time from design to production, enabling businesses to respond to customer demands more effectively. As a result, it has become an indispensable technique for companies seeking to maintain a competitive edge in the injection molding sector.

3. Benefits of Rapid Tooling in Injection Molding

The adoption of rapid tooling in injection molding offers numerous advantages. Here, we explore the most significant benefits that can influence a company's bottom line and operational efficiency.

3.1 Cost-effectiveness of Rapid Tooling

One of the primary advantages of rapid tooling is its **cost-effectiveness**. Traditional mold-making processes often require significant investments in materials, labor, and time. In contrast, rapid tooling minimizes these costs by utilizing technologies that reduce material waste and manufacturing time.

By shortening the production cycle, businesses can achieve faster returns on investment (ROI) and allocate resources more efficiently. Moreover, the ability to create prototypes quickly allows companies to test designs and make necessary adjustments before committing to full-scale production, further helping to manage costs.

3.2 Time Efficiency and Speed to Market

In today's market, **time is of the essence**. Companies that can launch products faster than their competitors often capture significant market share. Rapid tooling enhances **time efficiency** by dramatically reducing the time required to produce molds.

With the capacity to design, prototype, and manufacture molds in days rather than weeks or months, businesses can accelerate their product development cycles. This rapid turnaround enables companies to respond swiftly to market demands and trends, ensuring they remain relevant and competitive.

3.3 Design Flexibility and Iteration

Rapid tooling allows for increased **design flexibility** and easier iterations. Manufacturers can experiment with different mold designs without incurring significant costs or delays. This freedom to iterate leads to better product outcomes, as designers can refine and optimize their products based on testing and feedback.

Furthermore, rapid tooling supports customization, making it possible to develop unique products tailored to specific customer requirements. This adaptability can be a crucial differentiator in a crowded market.

3.4 Enhanced Production Quality

Quality is paramount in manufacturing, and rapid tooling contributes to **enhanced production quality**. The advanced techniques used in rapid tooling, such as 3D printing, enable the creation of highly precise molds with intricate details.

These molds not only improve the overall quality of the final products but also reduce defects and rework rates. Consistent quality enhances customer satisfaction and builds brand loyalty, which are critical for long-term success.

3.5 Sustainability Advantages

As industries increasingly prioritize sustainability, rapid tooling offers several **environmental benefits**. The reduction in material waste, energy consumption, and production time aligns with eco-friendly manufacturing practices.

Additionally, the use of recycled materials in rapid tooling processes can further minimize the environmental impact. Companies adopting sustainable practices not only contribute positively to the planet but also appeal to environmentally conscious consumers, enhancing their market position.

4. Implementing Rapid Tooling in Your Manufacturing Process

To successfully integrate rapid tooling into your injection molding operations, consider the following steps:

1. **Assess Your Needs**: Evaluate your current production processes and identify areas where rapid tooling can add value.

2. **Invest in Technology**: Acquire the necessary equipment and software for rapid tooling, such as 3D printers and design software.

3. **Train Your Team**: Ensure that your staff is adequately trained to utilize new technologies effectively.

4. **Collaborate with Experts**: Partner with suppliers and technology providers who specialize in rapid tooling to leverage their expertise.

5. **Monitor and Optimize**: Continuously assess the effectiveness of rapid tooling in your operations and make adjustments as necessary to maximize benefits.

5. Case Studies: Successful Rapid Tooling Implementations

Examining real-world examples can provide valuable insights into the effectiveness of rapid tooling. Here are a few case studies showcasing successful implementations:

- **Company A**: A consumer electronics manufacturer adopted rapid tooling and reduced their mold-making time by 70%. This allowed them to release a new product line ahead of competitors, significantly increasing their market share.

- **Company B**: A medical device company utilized rapid tooling to create custom molds for specialized products. This adaptation resulted in a 50% reduction in development costs and improved product quality due to precise mold designs.

- **Company C**: An automotive parts supplier integrated rapid tooling into their production process, which led to enhanced design flexibility. The ability to quickly prototype and test new designs resulted in faster product iterations and increased customer satisfaction.

6. The Future of Rapid Tooling in Injection Molding

Looking ahead, rapid tooling is poised to transform the injection molding landscape further. Continued advancements in technology, such as AI-driven design software and improved materials for 3D printing, will enhance the capabilities of rapid tooling.

As more companies recognize the advantages of this innovative approach, we can expect widespread adoption across various industries. The future of rapid tooling is not only about faster production but also about creating smarter, more sustainable manufacturing processes that align with modern consumer expectations.

7. FAQs About Rapid Tooling in Injection Molding

What is rapid tooling?

Rapid tooling is a manufacturing process that allows for the fast production of molds used in injection molding, utilizing advanced technologies such as 3D printing and CNC machining.

How does rapid tooling save costs?

By reducing material waste, production time, and labor costs, rapid tooling helps companies achieve faster returns on investment and optimize resource allocation.

Can rapid tooling accommodate custom designs?

Yes, rapid tooling offers design flexibility, enabling manufacturers to create custom molds tailored to specific product requirements quickly.

What industries benefit from rapid tooling?

Rapid tooling is beneficial across various industries, including consumer electronics, automotive, medical devices, and packaging.

Is rapid tooling environmentally friendly?

Yes, rapid tooling reduces material waste and energy consumption, aligning with sustainable manufacturing practices and appealing to eco-conscious consumers.

8. Conclusion

Rapid tooling is revolutionizing the injection molding industry by unlocking unprecedented efficiency and flexibility in manufacturing processes. Its cost-effectiveness, time efficiency, design flexibility, enhanced production quality, and sustainability advantages position it as a game-changer for businesses looking to thrive in a competitive landscape. As technology continues to advance, the potential for rapid tooling will only grow, making it an essential strategy for manufacturers aiming to stay ahead of the curve. Embracing rapid tooling not only benefits production but also paves the way for innovation and responsiveness to ever-evolving market needs.

rapid tooling injection molding

Related news

2024-11-15