Understanding Plastic Insert Molding: A Comprehensive Guide for Professionals

Time:

2025-09-24 11:40

Source:

Plastic insert molding is an innovative manufacturing process that combines traditional injection molding with the insertion of pre-formed components into the mold. This technique allows for the production of complex parts that integrate metal, plastic, or other materials, enhancing the functionality and performance of the final product. It is widely used in various industries, including automotive, electronics, medical devices, and consumer goods, due to its efficiency and versatility.

One of the primary advantages of plastic insert molding is its ability to reduce assembly time and costs. By incorporating additional components, such as metal inserts or electronic circuits, directly into the molded part, manufacturers can eliminate the need for secondary assembly processes. This not only streamlines production but also minimizes the risk of errors and improves overall product quality.

Moreover, plastic insert molding provides enhanced mechanical properties, improving the durability and strength of the final product. The integration of different materials can result in parts that are lighter yet stronger than traditional components made solely from plastic. This is particularly beneficial in industries that demand lightweight solutions without compromising on performance, such as aerospace and automotive.

Another critical aspect to consider in plastic insert molding is the selection of materials. The choice of plastic resin plays a significant role in the performance of the final product. Commonly used materials include thermoplastics, such as ABS (Acrylonitrile Butadiene Styrene), polycarbonate, and nylon, each offering distinct benefits and characteristics. Additionally, the compatibility of the insert material with the plastic is vital to ensure a strong bond and optimal performance.

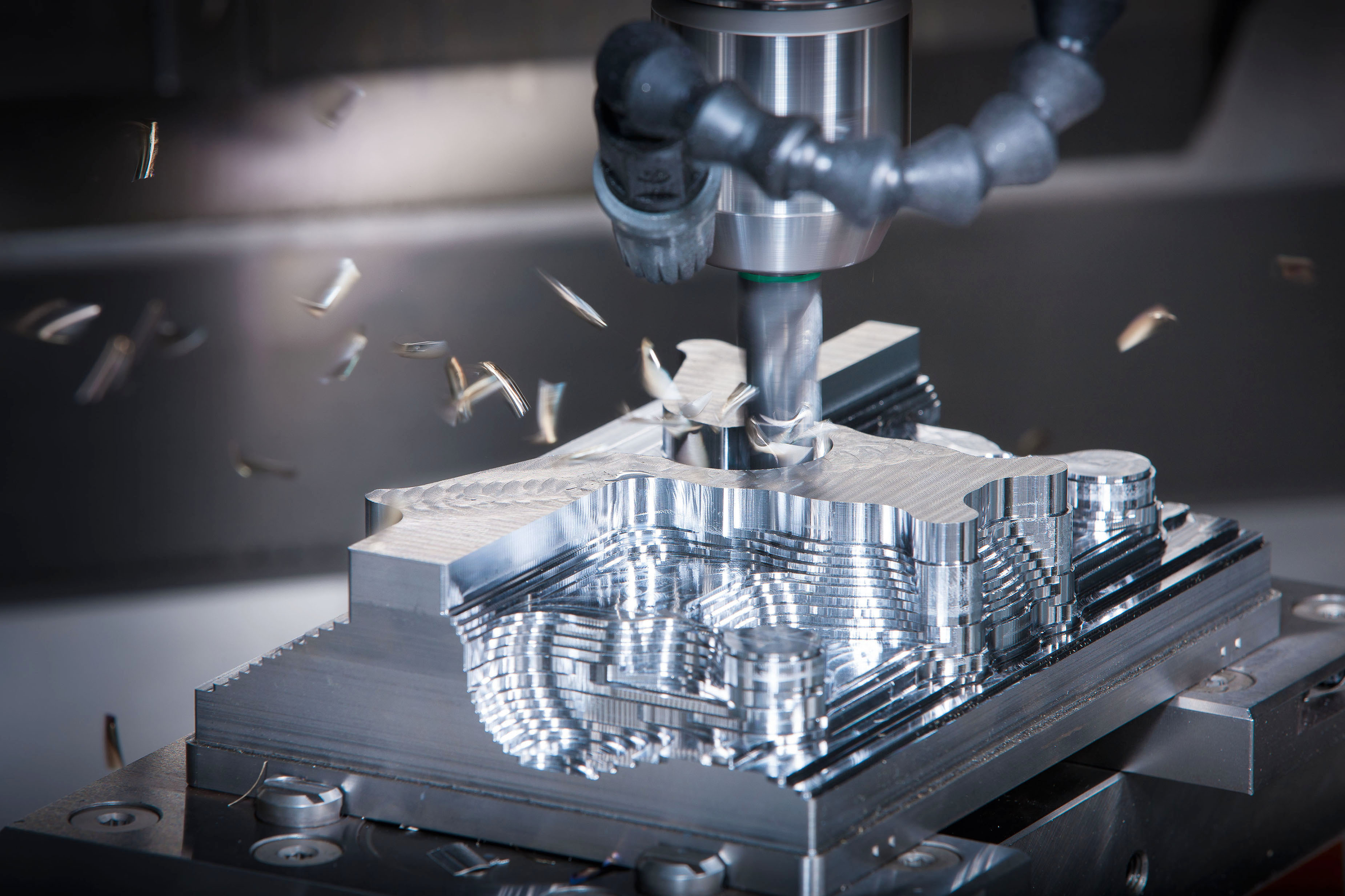

The design of the mold itself is equally important in the plastic insert molding process. Precision engineering is required to create molds that can accommodate the inserts while ensuring uniform flow and temperature control during the injection molding phase. Advanced technologies, such as computer-aided design (CAD) and simulation software, are often employed to optimize mold designs and predict potential issues before production begins.

In conclusion, plastic insert molding is an efficient and innovative manufacturing technique that offers numerous advantages for producing complex components. By understanding the intricacies of this process, including material selection and mold design, professionals in the machining and molding industries can leverage its benefits to improve product performance and reduce costs. As the demand for high-quality, integrated components continues to rise, mastering plastic insert molding will be essential for staying competitive in the market.

One of the primary advantages of plastic insert molding is its ability to reduce assembly time and costs. By incorporating additional components, such as metal inserts or electronic circuits, directly into the molded part, manufacturers can eliminate the need for secondary assembly processes. This not only streamlines production but also minimizes the risk of errors and improves overall product quality.

Moreover, plastic insert molding provides enhanced mechanical properties, improving the durability and strength of the final product. The integration of different materials can result in parts that are lighter yet stronger than traditional components made solely from plastic. This is particularly beneficial in industries that demand lightweight solutions without compromising on performance, such as aerospace and automotive.

Another critical aspect to consider in plastic insert molding is the selection of materials. The choice of plastic resin plays a significant role in the performance of the final product. Commonly used materials include thermoplastics, such as ABS (Acrylonitrile Butadiene Styrene), polycarbonate, and nylon, each offering distinct benefits and characteristics. Additionally, the compatibility of the insert material with the plastic is vital to ensure a strong bond and optimal performance.

The design of the mold itself is equally important in the plastic insert molding process. Precision engineering is required to create molds that can accommodate the inserts while ensuring uniform flow and temperature control during the injection molding phase. Advanced technologies, such as computer-aided design (CAD) and simulation software, are often employed to optimize mold designs and predict potential issues before production begins.

In conclusion, plastic insert molding is an efficient and innovative manufacturing technique that offers numerous advantages for producing complex components. By understanding the intricacies of this process, including material selection and mold design, professionals in the machining and molding industries can leverage its benefits to improve product performance and reduce costs. As the demand for high-quality, integrated components continues to rise, mastering plastic insert molding will be essential for staying competitive in the market.

plastic insert molding

Previous Page

Previous Page

Related news

2024-11-15