Exploring Design Considerations for Low Quantity Injection Molding Projects: A Comprehensive Guide

Time:

2025-06-22 09:20

Source:

Exploring Design Considerations for Low Quantity Injection Molding Projects

Table of Contents

- 1. Introduction to Low Quantity Injection Molding

- 2. Understanding the Injection Molding Process

- 3. Key Design Considerations for Low Quantity Projects

- 3.1 Part Design and Its Implications

- 3.2 Selecting the Right Materials

- 3.3 Tooling Choices for Low Volume Production

- 3.4 Enhancing Production Efficiency

- 4. Cost Considerations in Low Quantity Injection Molding

- 5. Prototyping and Testing Before Production

- 6. Case Studies: Successful Low Quantity Injection Molding Projects

- 7. Future Trends in Low Quantity Injection Molding

- 8. FAQs on Low Quantity Injection Molding

- 9. Conclusion

1. Introduction to Low Quantity Injection Molding

Low quantity injection molding is revolutionizing the manufacturing sector, especially for projects requiring fewer parts than traditional methods allow. This technique is particularly advantageous for startups, niche markets, and industries focused on rapid prototyping. By understanding the unique characteristics of low quantity injection molding, manufacturers can make informed decisions that lead to highly efficient and cost-effective production.

2. Understanding the Injection Molding Process

Injection molding is a manufacturing process where molten plastic is injected into a mold to create parts of varying complexity. The process is known for its speed and precision, making it ideal for producing intricate designs with high repeatability. For low quantity projects, injection molding can significantly reduce lead times compared to other fabrication methods.

2.1 Key Stages of the Injection Molding Process

The injection molding process consists of several key stages:

- **Melt**: Plastic pellets are heated until they melt into a viscous state.

- **Inject**: The molten plastic is injected into the mold cavity under high pressure.

- **Cool**: The material cools and solidifies within the mold.

- **Eject**: Once sufficiently cooled, the mold opens and ejects the finished part.

Understanding these stages is crucial for successfully navigating the nuances of low quantity injection molding projects.

3. Key Design Considerations for Low Quantity Projects

When embarking on low quantity injection molding projects, several design considerations can impact overall success.

3.1 Part Design and Its Implications

Part design plays a pivotal role in the effectiveness of the injection molding process. Key aspects to consider include:

- **Wall Thickness**: Consistent wall thickness is essential to ensure uniform cooling and minimize defects.

- **Draft Angles**: Implementing draft angles facilitates easier ejection from the mold, reducing the risk of damage.

- **Radii and Fillets**: Using rounded edges can help prevent stress concentrations, improving the longevity of the part.

By prioritizing these design elements from the outset, manufacturers can enhance both functionality and manufacturability.

3.2 Selecting the Right Materials

Material selection is another critical factor in low quantity injection molding. The choice of material affects everything from the part's physical properties to production costs. Common materials include:

- **ABS**: Known for its strength and impact resistance, ideal for prototype applications.

- **Polypropylene**: Lightweight and chemical-resistant, often used for consumer goods.

- **Nylon**: Offers excellent durability and flexibility, suitable for functional parts.

Evaluating the specific requirements of the project will guide the selection of the most suitable material.

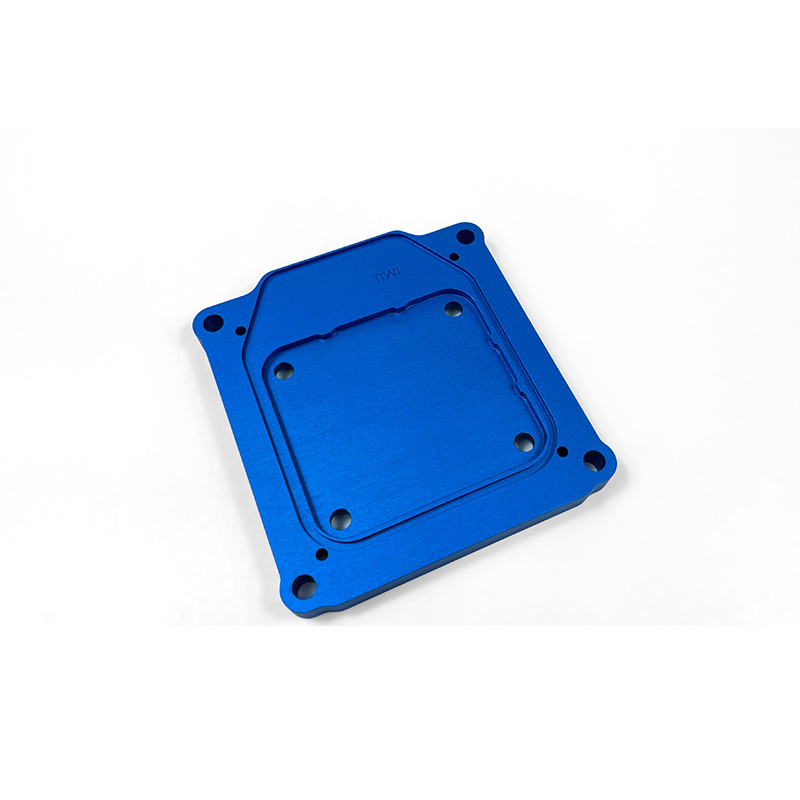

3.3 Tooling Choices for Low Volume Production

Tooling represents one of the most significant costs in injection molding but can be optimized for low volume production. Options include:

- **Aluminum Molds**: Faster and cheaper to produce than steel molds, but limited in durability.

- **3D Printed Molds**: Emerging technology allows rapid prototyping of molds for low-volume runs, significantly reducing initial costs.

Selecting the right tooling method can dramatically influence both the quality of the parts produced and the overall project cost.

3.4 Enhancing Production Efficiency

To maximize efficiency in low quantity injection molding projects, manufacturers should consider:

- **Cycle Times**: Shortening cycle times can lead to quicker turnaround and increased output.

- **Automation**: Employing automated processes can minimize manual intervention, reducing labor costs and increasing precision.

- **Quality Control**: Implementing rigorous quality control measures throughout the production process can mitigate defects and enhance product reliability.

By focusing on these efficiency-enhancing strategies, manufacturers can improve their output while maintaining high-quality standards.

4. Cost Considerations in Low Quantity Injection Molding

Understanding costs associated with low quantity injection molding is crucial for project budgeting. Factors influencing costs include:

- **Material Costs**: Fluctuations in raw material prices can significantly affect overall expenses.

- **Tooling Costs**: As mentioned previously, selecting the right tooling can reduce upfront costs.

- **Production Volume**: While low quantity runs typically incur higher per-unit costs, they can sometimes be more economical than traditional methods for short runs.

Performing a thorough cost analysis is essential for ensuring the financial viability of a low volume project.

5. Prototyping and Testing Before Production

Before moving into full-scale production, it is vital to prototype and test designs. Prototyping allows for:

- **Design Validation**: Ensuring the part meets functional and aesthetic requirements.

- **User Feedback**: Gaining insights from potential users can guide further refinements.

- **Testing for Performance**: Conducting tests to evaluate strength, flexibility, and other essential characteristics ensures the final product will perform as intended.

Investing time and resources into prototyping can save significant costs and time in the later stages of production.

6. Case Studies: Successful Low Quantity Injection Molding Projects

Examining real-world examples can provide valuable insights into best practices. Here are a few successful low quantity injection molding projects:

- **Consumer Electronics Prototype**: A startup utilized aluminum molds to create a prototype casing for a new electronic device. This approach allowed for rapid iterations based on user feedback.

- **Medical Device Component**: In the medical field, a company produced a low quantity of specialized components using 3D printed molds, enabling them to enter the market quickly without significant investment in tooling.

These case studies highlight the diverse applications of low quantity injection molding across industries.

7. Future Trends in Low Quantity Injection Molding

The future of low quantity injection molding is promising, with several trends emerging:

- **Sustainable Materials**: Increasing demand for eco-friendly options is driving innovations in biodegradable and recycled plastics.

- **Advanced Technologies**: Developments in automation and AI are improving production efficiency and quality control.

- **Customization**: As consumer preferences shift towards personalized products, low quantity injection molding provides the flexibility needed to meet these demands.

Staying informed about these trends will position manufacturers to leverage new opportunities in the market.

8. FAQs on Low Quantity Injection Molding

What is low quantity injection molding?

Low quantity injection molding refers to the production of plastic parts in smaller volumes, typically less than 10,000 units, using injection molding technology.

What materials are best for low quantity injection molding?

Common materials include ABS, polypropylene, and nylon, chosen based on the specific requirements of the project.

How can I reduce costs in low quantity injection molding?

You can reduce costs by selecting the right materials, opting for aluminum or 3D printed molds, and optimizing production processes for efficiency.

What is the role of prototyping in injection molding?

Prototyping is critical for validating designs, gathering feedback, and ensuring the performance of parts before full-scale production begins.

Are there any limitations to low quantity injection molding?

Yes, while low quantity injection molding offers flexibility, it may have higher per-unit costs compared to high volume production, and tooling can still be a significant investment.

9. Conclusion

In conclusion, low quantity injection molding can be a game-changer for manufacturers looking to produce high-quality, intricate parts without the burden of large volume commitments. By paying careful attention to design considerations, selecting appropriate materials and tooling, and investing in prototyping and testing, companies can maximize their success in this dynamic sector. As the industry continues to evolve, staying informed about emerging trends will further enhance the effectiveness and efficiency of low quantity injection molding projects.

low quantity injection molding

Previous Page

Previous Page

Related news

2024-11-15