The Crucial Role of Precision in Modern Injection Molding Techniques: Unlocking the Future of Manufacturing

Time:

2025-08-26 16:40

Source:

The Crucial Role of Precision in Modern Injection Molding Techniques

Table of Contents

1. Understanding Injection Molding

2. The Importance of Precision in Injection Molding

3. Key Factors Influencing Precision in Injection Molding

3.1 Mold Design and Construction

3.2 Material Selection and Properties

3.3 Machine Calibration and Maintenance

4. Advanced Technologies Enhancing Precision

4.1 Computer-Aided Design (CAD)

4.2 3D Printing in Mold Making

4.3 Automation and Robotics

5. Best Practices for Achieving Precision in Injection Molding

5.1 Quality Control Measures

5.2 Continuous Training for Operators

6. Case Studies: Precision in Action

7. FAQs About Precision in Injection Molding

8. Conclusion

1. Understanding Injection Molding

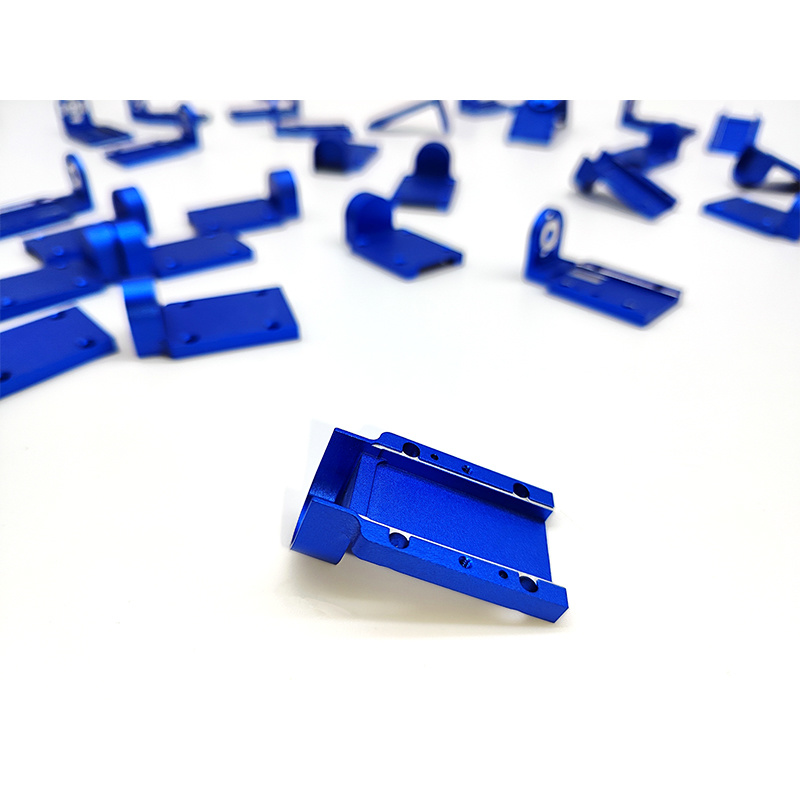

Injection molding is a manufacturing process widely used for producing plastic parts. This method involves injecting molten plastic into a pre-designed mold, allowing it to cool and solidify into the desired shape. From automotive components to household items, injection molding is integral to numerous industries, making its precision crucial for product quality and performance.

2. The Importance of Precision in Injection Molding

Precision in injection molding directly impacts the quality, consistency, and cost-effectiveness of the final product. Even minor deviations in the molding process can lead to defects, affecting functionality and aesthetic appeal. Therefore, maintaining high precision ensures that products meet stringent industry standards and customer expectations.

3. Key Factors Influencing Precision in Injection Molding

3.1 Mold Design and Construction

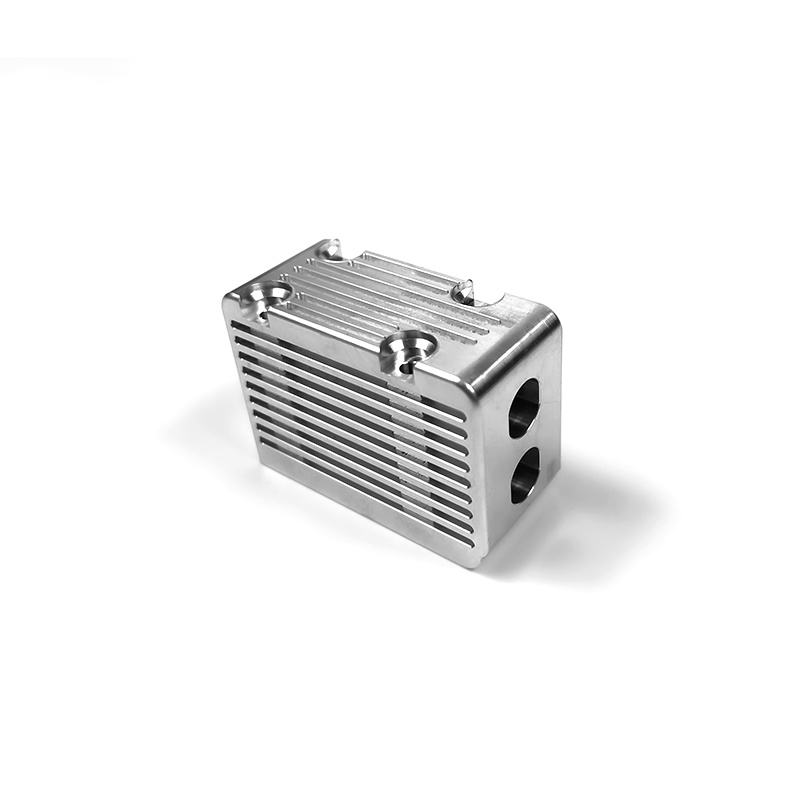

The design and construction of molds significantly affect the precision of the injection molding process. High-quality molds must be engineered to exact specifications to ensure uniformity in each produced part. Factors such as mold temperature, cooling channels, and venting systems play a vital role in achieving the desired accuracy and consistency.

3.2 Material Selection and Properties

Choosing the right materials for the injection molding process is essential. Different plastics have varying properties, including flow rates, thermal expansion, and shrinkage. Understanding these characteristics and how they interact with the mold design is critical in maintaining precision throughout the production process.

3.3 Machine Calibration and Maintenance

Regular calibration and maintenance of injection molding machines are vital for sustaining precision. Machines must be meticulously set to ensure accurate injection pressures, temperatures, and cycle times. Neglecting machine upkeep can lead to inconsistencies and defects in the finished products.

4. Advanced Technologies Enhancing Precision

4.1 Computer-Aided Design (CAD)

Modern injection molding heavily relies on advanced CAD software to design intricate molds. CAD allows engineers to create precise 3D models, visualize the molding process, and identify potential design flaws before mold fabrication. This proactive approach enhances accuracy and reduces the risk of costly revisions during production.

4.2 3D Printing in Mold Making

The advent of 3D printing technology has revolutionized mold making. Rapid prototyping allows manufacturers to create complex molds with high precision at a fraction of the time and cost of traditional methods. This technology not only accelerates the design process but also enables the production of intricate geometries that were previously unfeasible.

4.3 Automation and Robotics

Integrating automation and robotics into the injection molding process enhances precision and efficiency. Automated systems can perform repetitive tasks with consistent accuracy, reducing human error. Additionally, robotics can facilitate intricate assembly and inspection processes, further ensuring that quality standards are met.

5. Best Practices for Achieving Precision in Injection Molding

5.1 Quality Control Measures

Implementing rigorous quality control measures is vital for maintaining precision in injection molding. Regular inspections, testing, and monitoring of production parameters can help identify deviations early and correct them before they lead to defective products. Utilizing statistical process control (SPC) techniques can also assist in maintaining consistent quality.

5.2 Continuous Training for Operators

A skilled workforce is crucial for achieving high precision in injection molding. Continuous training programs for operators ensure they stay updated on the latest technologies and best practices in the industry. Knowledgeable operators can better identify issues, make informed decisions, and optimize the production process.

6. Case Studies: Precision in Action

Examining real-world applications of precision in injection molding can provide valuable insights. For example, a leading automotive manufacturer implemented advanced CAD and 3D printing technologies in their mold design process. This shift resulted in a 30% reduction in lead time and a significant increase in part accuracy, ultimately enhancing overall product quality.

In another instance, a consumer electronics company adopted automation in their injection molding operations. By using robotic arms for assembly and quality inspection, they achieved consistent product quality while reducing labor costs. These examples underscore the importance of precision and technological integration in modern manufacturing.

7. FAQs About Precision in Injection Molding

What is injection molding?

Injection molding is a manufacturing process used to produce plastic parts by injecting molten plastic into a mold, where it cools and solidifies.

Why is precision important in injection molding?

Precision is crucial because it affects the quality, consistency, and functionality of the final product. Even minor deviations can lead to defects and increased production costs.

How does mold design impact precision?

Proper mold design ensures uniformity and accuracy in each produced part. Factors such as cooling channels and venting systems play significant roles in maintaining precision.

What technologies enhance precision in injection molding?

Technologies such as CAD, 3D printing, and automation significantly improve precision by enabling accurate designs, rapid prototyping, and reducing human error.

What measures can be taken to ensure precision in injection molding?

Implementing quality control measures and providing continuous training for operators are essential for maintaining precision in injection molding processes.

8. Conclusion

Precision in modern injection molding techniques is not merely advantageous; it is essential for achieving high-quality products in today's competitive landscape. By focusing on advanced technologies, meticulous design, and stringent quality control measures, manufacturers can ensure consistent accuracy and reliability. Embracing these practices will not only enhance product quality but also drive innovation and efficiency in the ever-evolving manufacturing sector. As we continue to explore and implement cutting-edge technologies, the future of injection molding looks promising, paving the way for even greater precision and excellence.

injection molding precision

Previous Page

Previous Page

Related news

2024-11-15

2025-08-26