Understanding Plastic Insert Molding: An Essential Process in Precision Manufacturing

Time:

2025-08-06 14:40

Source:

Plastic insert molding is a specialized technique in the manufacturing industry, particularly within the realm of plastic molding and tooling. This process combines the principles of traditional injection molding with the inclusion of pre-formed inserts, which can be made from various materials including metal, plastic, or composite elements. The integration of inserts allows manufacturers to create complex parts that require additional functionality, such as added strength, conductivity, or aesthetic appeal.

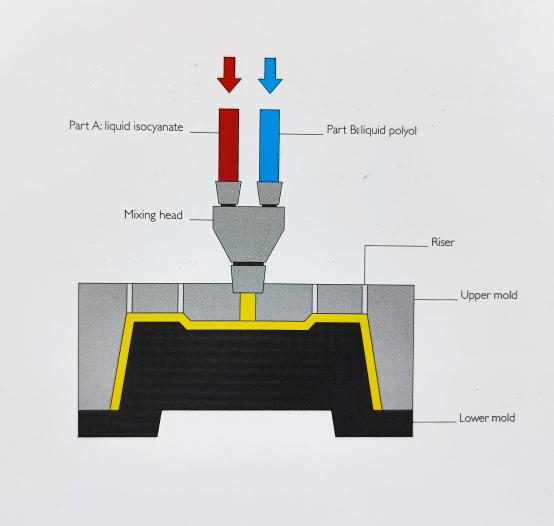

The process begins with the preparation of the mold, where the pre-formed inserts are strategically placed into the mold cavity. Once positioned, the injection molding machine introduces molten plastic into the cavity under high pressure. The plastic surrounds the inserts, creating a robust bond as it cools and solidifies. This method not only streamlines production by reducing assembly steps but also enhances the performance characteristics of the final product.

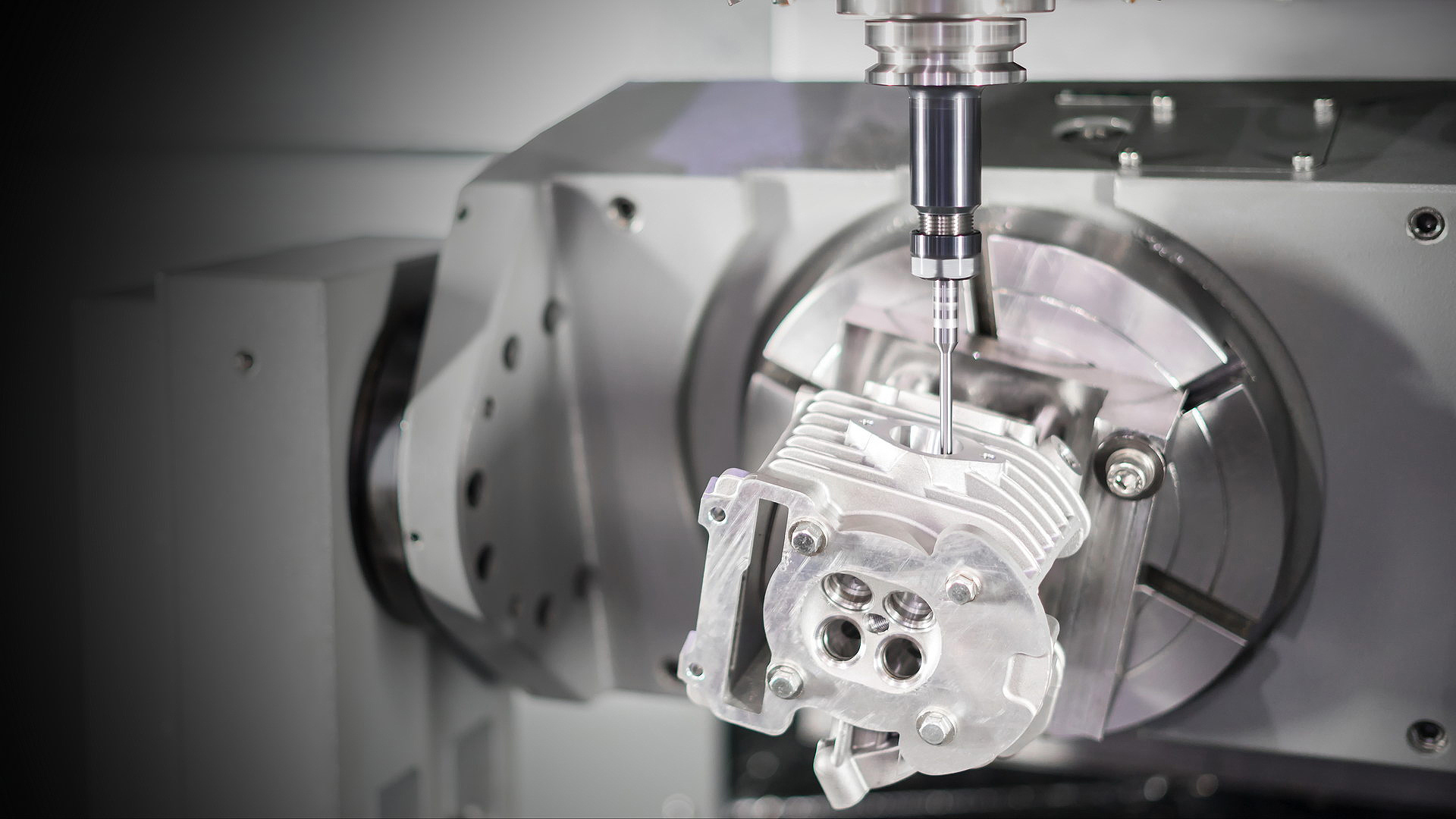

One of the primary advantages of plastic insert molding is its ability to produce intricate designs with high precision. This is particularly beneficial in industries such as automotive, electronics, and consumer goods, where components often require strict tolerances and complex shapes. With the help of advanced computer-aided design (CAD) software and state-of-the-art molding machines, manufacturers can achieve remarkable accuracy and repeatability in their production runs.

Moreover, plastic insert molding contributes to cost efficiency in production. By incorporating inserts directly during the molding process, manufacturers can eliminate the need for subsequent assembly operations, reducing labor costs and minimizing the risk of assembly-related defects. This integrated approach also decreases the overall production time, resulting in faster turnaround times for projects.

Additionally, the choice of materials for both the plastic and the inserts allows for customization tailored to specific applications. For instance, metal inserts can significantly enhance the mechanical strength of a plastic part, making it suitable for high-load applications. Similarly, the use of different plastics can impart various properties, such as heat resistance or electrical conductivity, thereby broadening the application potential of molded components.

In conclusion, plastic insert molding is a vital technique that merges efficiency with versatility in the manufacturing process. As industries continue to demand more complex and functional components, understanding the benefits and applications of this molding technique will empower manufacturers to innovate and stay competitive in a fast-evolving market. Embracing plastic insert molding can lead to enhanced product performance, reduced production costs, and greater customer satisfaction.

The process begins with the preparation of the mold, where the pre-formed inserts are strategically placed into the mold cavity. Once positioned, the injection molding machine introduces molten plastic into the cavity under high pressure. The plastic surrounds the inserts, creating a robust bond as it cools and solidifies. This method not only streamlines production by reducing assembly steps but also enhances the performance characteristics of the final product.

One of the primary advantages of plastic insert molding is its ability to produce intricate designs with high precision. This is particularly beneficial in industries such as automotive, electronics, and consumer goods, where components often require strict tolerances and complex shapes. With the help of advanced computer-aided design (CAD) software and state-of-the-art molding machines, manufacturers can achieve remarkable accuracy and repeatability in their production runs.

Moreover, plastic insert molding contributes to cost efficiency in production. By incorporating inserts directly during the molding process, manufacturers can eliminate the need for subsequent assembly operations, reducing labor costs and minimizing the risk of assembly-related defects. This integrated approach also decreases the overall production time, resulting in faster turnaround times for projects.

Additionally, the choice of materials for both the plastic and the inserts allows for customization tailored to specific applications. For instance, metal inserts can significantly enhance the mechanical strength of a plastic part, making it suitable for high-load applications. Similarly, the use of different plastics can impart various properties, such as heat resistance or electrical conductivity, thereby broadening the application potential of molded components.

In conclusion, plastic insert molding is a vital technique that merges efficiency with versatility in the manufacturing process. As industries continue to demand more complex and functional components, understanding the benefits and applications of this molding technique will empower manufacturers to innovate and stay competitive in a fast-evolving market. Embracing plastic insert molding can lead to enhanced product performance, reduced production costs, and greater customer satisfaction.

plastic insert molding

Previous Page

Previous Page

Related news

2024-11-15