Understanding the Essential Parts of Injection Molding: A Guide to Their Functionality

Time:

2025-08-31 21:20

Source:

Injection molding is a pivotal process in the manufacturing of plastic parts, widely utilized across various industries. Understanding the parts of the injection system is crucial for optimizing production, minimizing defects, and improving overall efficiency. Here, we will explore the essential components and their functionalities to enhance your knowledge in this field.

**1. Injection Unit**

The injection unit is where the plastic material is heated, melted, and injected into the mold. It typically consists of a hopper for feeding pellets, a barrel for melting the material, and a screw or plunger for injecting the molten plastic into the mold. The efficiency of the injection unit directly impacts cycle times and the quality of the final product.

**2. Clamping Unit**

This part of the injection molding machine is responsible for holding the mold in place during the injection process. The clamping unit ensures that the mold halves are securely closed to withstand the pressure of the injected plastic. A reliable clamping unit minimizes the risk of flash (excess material) and maintains the integrity of the mold throughout the production cycle.

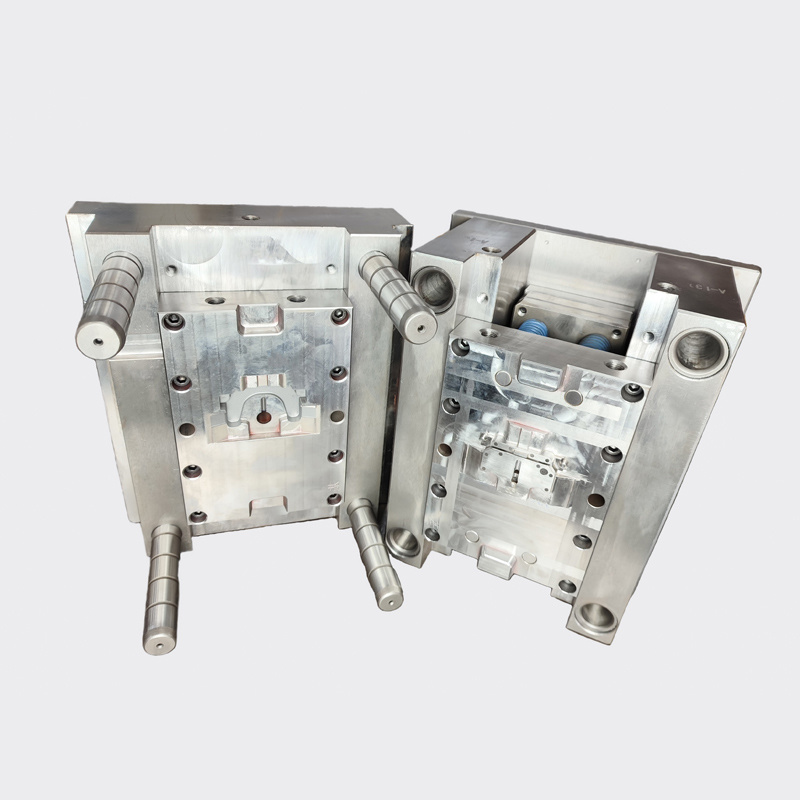

**3. Mold**

The mold is a critical element of the injection molding process, designed to shape the melted plastic into the desired form. Molds can be complex, with multiple cavities and intricate designs. They are typically made from durable materials like steel or aluminum, ensuring they can withstand multiple cycles without significant wear. Proper mold design and maintenance are key factors in the quality and efficiency of production.

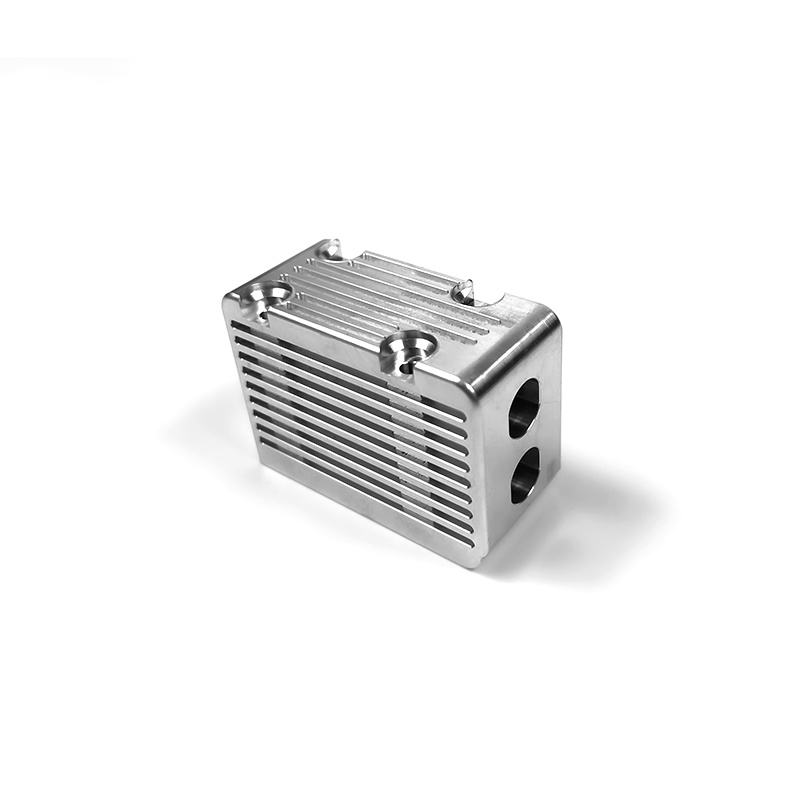

**4. Cooling System**

Once the molten plastic is injected into the mold, it needs to be cooled and solidified. The cooling system, often comprising channels running through the mold, circulates a cooling fluid to remove heat from the molded part. Efficient cooling is essential for reducing cycle times and ensuring dimensional accuracy of the finished product.

**5. Ejection System**

After the plastic has cooled and solidified, the ejection system comes into play. This system is responsible for removing the finished part from the mold. It typically includes ejector pins or plates that push the molded item out without causing damage. An effective ejection system ensures minimal downtime and prevents defects in the finished product.

In conclusion, understanding the parts of the injection molding process is vital for anyone involved in the manufacturing and machining industry. Each component plays a significant role in ensuring efficient production and high-quality outputs. By optimizing these parts, manufacturers can enhance their operational efficiency and meet the demands of an increasingly competitive market.

**1. Injection Unit**

The injection unit is where the plastic material is heated, melted, and injected into the mold. It typically consists of a hopper for feeding pellets, a barrel for melting the material, and a screw or plunger for injecting the molten plastic into the mold. The efficiency of the injection unit directly impacts cycle times and the quality of the final product.

**2. Clamping Unit**

This part of the injection molding machine is responsible for holding the mold in place during the injection process. The clamping unit ensures that the mold halves are securely closed to withstand the pressure of the injected plastic. A reliable clamping unit minimizes the risk of flash (excess material) and maintains the integrity of the mold throughout the production cycle.

**3. Mold**

The mold is a critical element of the injection molding process, designed to shape the melted plastic into the desired form. Molds can be complex, with multiple cavities and intricate designs. They are typically made from durable materials like steel or aluminum, ensuring they can withstand multiple cycles without significant wear. Proper mold design and maintenance are key factors in the quality and efficiency of production.

**4. Cooling System**

Once the molten plastic is injected into the mold, it needs to be cooled and solidified. The cooling system, often comprising channels running through the mold, circulates a cooling fluid to remove heat from the molded part. Efficient cooling is essential for reducing cycle times and ensuring dimensional accuracy of the finished product.

**5. Ejection System**

After the plastic has cooled and solidified, the ejection system comes into play. This system is responsible for removing the finished part from the mold. It typically includes ejector pins or plates that push the molded item out without causing damage. An effective ejection system ensures minimal downtime and prevents defects in the finished product.

In conclusion, understanding the parts of the injection molding process is vital for anyone involved in the manufacturing and machining industry. Each component plays a significant role in ensuring efficient production and high-quality outputs. By optimizing these parts, manufacturers can enhance their operational efficiency and meet the demands of an increasingly competitive market.

parts of the injection

Related news

2024-11-15

2025-08-26