Top 5 Applications of Insert Molding in Modern Manufacturing

Time:

2025-09-04 15:41

Source:

Top 5 Applications of Insert Molding in Modern Manufacturing

Insert molding, a specialized technique that combines plastic and metal components into a single, unified part, is revolutionizing the landscape of modern manufacturing. This process not only enhances product performance but also streamlines production efficiency. In this article, we will delve into the top five applications of insert molding, examining how this innovative technique plays a crucial role in various industries.

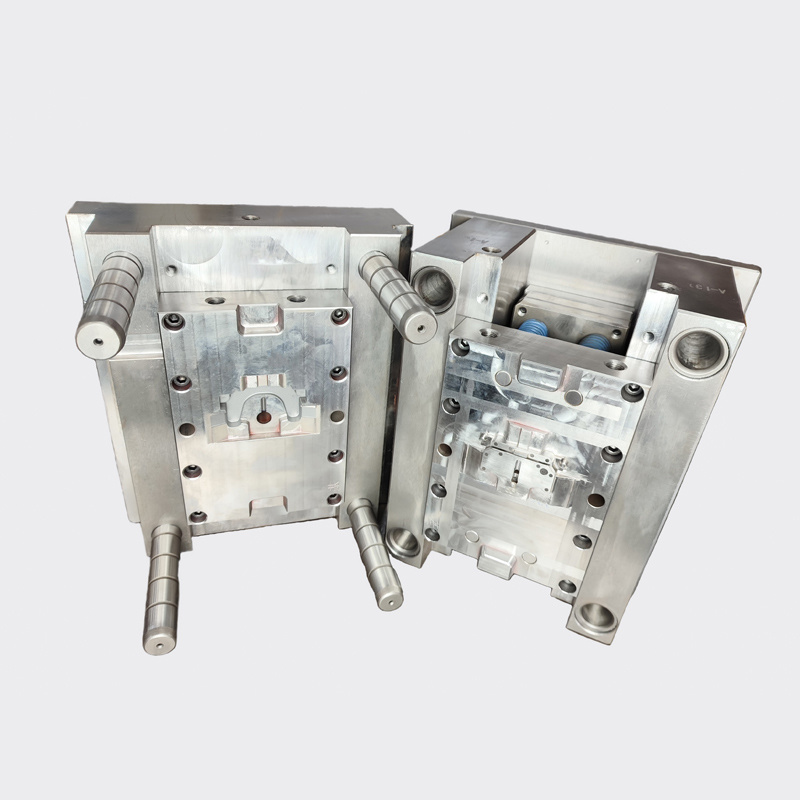

Understanding Insert Molding

Before exploring its applications, it's essential to understand what insert molding entails. This manufacturing process involves placing a pre-formed component, such as metal or another plastic part, into a mold, followed by injecting molten plastic around it. Once cooled, the result is a robust, integrated product. The advantages of insert molding include reduced assembly time, improved durability, and enhanced design flexibility.

1. Automotive Industry: Enhancing Performance and Safety

The automotive sector is one of the foremost industries benefiting from insert molding. Here are a few specific applications where insert molding proves impactful:

A. Integration of Functional Components

Insert molding enables the integration of various components—such as clips, brackets, and electrical connectors—into single parts. This integration helps reduce the number of separate components, leading to lighter and more efficient vehicle designs.

B. Improved Electrical Insulation

As vehicles become more technologically advanced, electrical insulation becomes paramount. Insert molding allows manufacturers to encapsulate wires and connectors within a plastic housing, providing robust protection against moisture and vibrations.

Case Study: Seatbelt Components

In modern vehicles, insert molded seatbelt components demonstrate how this technique can enhance safety features. By embedding metal components within durable plastic, manufacturers can create reliable, lightweight seatbelt mechanisms that withstand significant stress during accidents.

2. Consumer Electronics: Streamlining Complex Assemblies

Consumer electronics represent another sector where insert molding is rapidly gaining traction. The need for compact, aesthetically pleasing, and functional designs drives the adoption of this technology.

A. Simplifying Assembly Processes

Insert molding reduces the complexity of electronic device assemblies by combining multiple parts into one. This simplification accelerates production timelines and reduces assembly costs, which is crucial in the competitive electronics market.

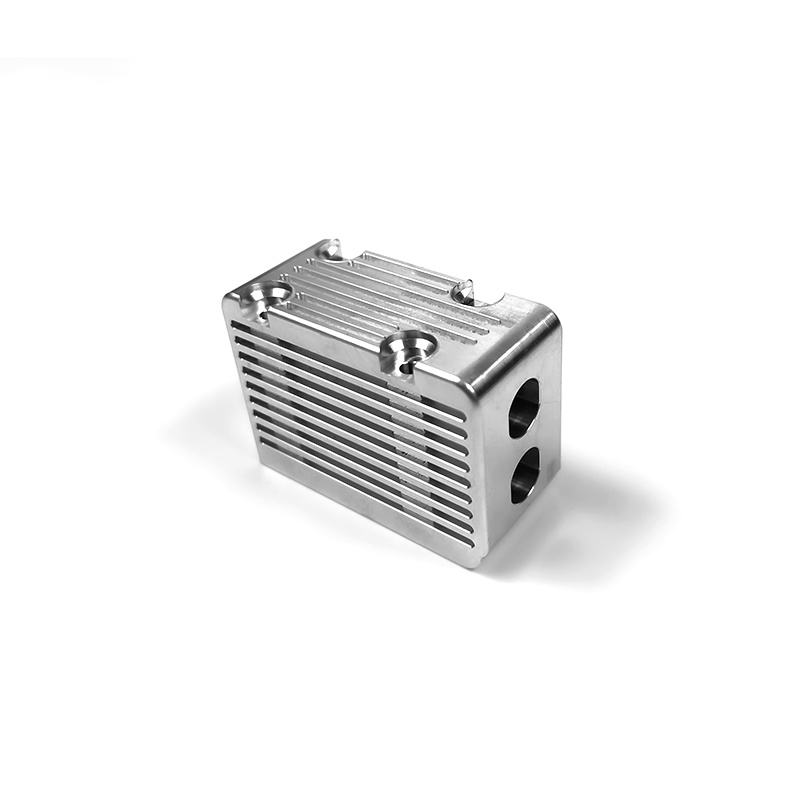

B. Enhancing Heat Dissipation

In electronics, managing heat is critical for device longevity. Insert molding allows manufacturers to create components that efficiently dissipate heat, offering better performance in devices like smartphones, laptops, and gaming consoles.

Case Study: Smartphone Casings

Smartphone manufacturers are leveraging insert molding to design casings that integrate structural elements while maintaining sleek aesthetics. This integration streamlines production and results in thinner, lighter devices with improved heat management.

3. Medical Devices: Ensuring Performance and Sterility

Insert molding plays a vital role in the production of medical devices, where precision, safety, and sterility are paramount.

A. Customization of Components

Medical devices often require unique features tailored to specific applications. Insert molding facilitates the creation of custom components, such as housings for sensors or delivery systems, that meet stringent regulatory requirements.

B. Promoting Sterility and Safety

Using insert molding reduces the need for multiple assembly steps, minimizing the risk of contamination. This is particularly crucial in applications such as surgical instruments and drug delivery systems, where sterility is non-negotiable.

Case Study: Surgical Tool Handles

Surgical tools often utilize insert molding to create handles that combine ergonomic design with high durability. By embedding metal parts within a plastic grip, manufacturers ensure that these tools are both comfortable to use and capable of withstanding rigorous sterilization processes.

4. Aerospace Industry: Meeting Stringent Standards

The aerospace industry demands materials and components that can withstand extreme conditions while adhering to strict safety regulations. Insert molding offers several advantages in this sector.

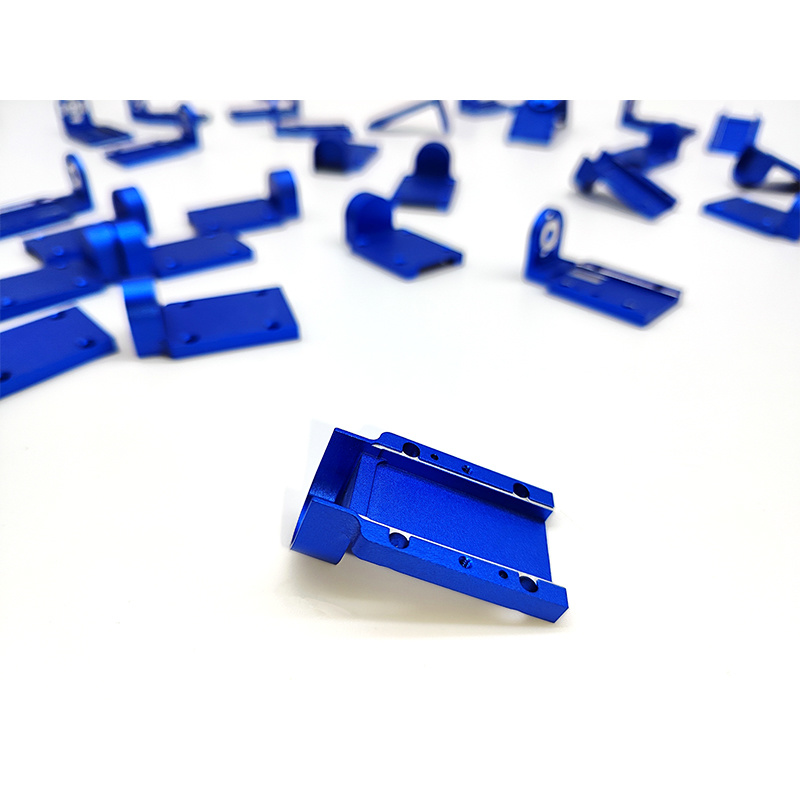

A. Lightweight Components

Reducing weight in aircraft is crucial for fuel efficiency. Insert molding enables the creation of lightweight parts that do not compromise strength, helping manufacturers produce more efficient aircraft.

B. Complex Geometries

The aerospace sector often requires components with intricate designs. Insert molding allows for the fabrication of complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods.

Case Study: Aircraft Instrument Panels

Instrument panels in aircraft benefit significantly from insert molding technology. Manufacturers can create panels that integrate multiple functional components, such as switches and displays, into a single, streamlined unit, enhancing both functionality and aesthetics.

5. Industrial Equipment: Boosting Efficiency and Reliability

In the realm of industrial equipment, insert molding is increasingly being applied to enhance operational efficiency and product reliability.

A. Reduction in Production Time

By combining parts through insert molding, manufacturers can significantly reduce production time. Fewer components mean fewer steps in the assembly process, leading to faster turnaround times.

B. Enhancing Durability

Industrial equipment often operates under harsh conditions. Insert molding creates durable components that can withstand mechanical stress and environmental challenges, ensuring long-lasting performance.

Case Study: Machinery Control Panels

Control panels for industrial machinery often incorporate insert molded components. By embedding connectors and switches into durable casings, manufacturers create panels that are not only easier to assemble but also more resistant to wear and tear.

Conclusion: The Future of Insert Molding in Manufacturing

Insert molding is undoubtedly revolutionizing modern manufacturing across various industries. Its ability to streamline production, enhance product durability, and allow for innovative designs makes it an invaluable technique. As technology continues to advance, the applications of insert molding will only expand, further shaping the future of manufacturing. By integrating insert molding into their processes, manufacturers can ensure they stay ahead of the competition, producing high-quality products that meet the evolving demands of consumers and industries alike.

FAQs About Insert Molding

1. What materials are commonly used in insert molding?

Insert molding typically uses a combination of plastics, such as ABS, polycarbonate, and nylon, alongside metals like aluminum and steel.

2. How does insert molding compare to traditional molding methods?

Insert molding combines multiple manufacturing steps into one process, reducing assembly time and improving product integrity compared to traditional molding methods.

3. What are the cost implications of using insert molding?

While initial setup costs may be higher, insert molding can lead to significant cost savings in production efficiency and reduced assembly costs over time.

4. Can insert molding be used for small-scale production?

Yes, insert molding is versatile and can be adapted for both large-scale and small-scale production runs, making it suitable for various manufacturing needs.

5. What industries are best suited for insert molding technology?

Industries such as automotive, consumer electronics, medical devices, aerospace, and industrial equipment significantly benefit from insert molding due to its efficiency and product enhancement capabilities.

overmolding insert molding

Previous Page

Previous Page

Related news

2024-11-15

2025-08-26