Understanding Rapid Tooling Injection Molding: A Game Changer in the Manufacturing Industry

Time:

2025-06-25 09:20

Source:

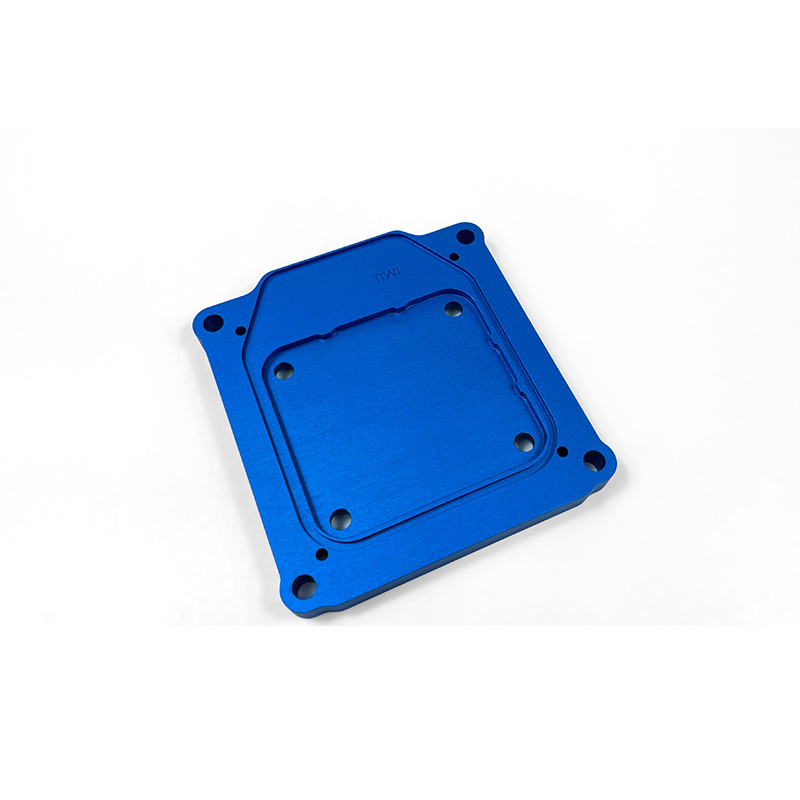

Rapid tooling injection molding is an innovative manufacturing process that bridges the gap between prototyping and mass production. In a fast-paced industry where time-to-market is crucial, rapid tooling offers manufacturers the ability to produce high-quality plastic parts quickly and cost-effectively. This method utilizes advanced techniques to create molds in a significantly reduced timeframe, making it a favored choice for many companies in the plastic manufacturing sector.

The core advantage of rapid tooling injection molding lies in its speed. Traditional injection molding requires extensive lead times for mold creation, often taking weeks or even months. However, rapid tooling can drastically shorten this period to just a few days or weeks, depending on the complexity of the design. This acceleration allows companies to respond to market demands more swiftly, aligning production schedules with consumer needs and trends.

Another vital aspect of rapid tooling is its cost efficiency. While traditional mold-making techniques can be prohibitively expensive, especially for small production runs, rapid tooling allows manufacturers to lower their upfront investment. The use of materials such as aluminum or 3D printed components for molds significantly reduces costs without sacrificing quality. This makes it an attractive option for businesses that need to test new products or enter new markets without committing to large-scale production.

The process of rapid tooling injection molding generally involves several steps. Initially, a digital model of the part is created using CAD software. Once the design is finalized, the mold is produced using techniques like CNC machining or additive manufacturing. After the mold is ready, it is installed in an injection molding machine, where melted plastic is injected into the mold cavity to form the desired shape. This streamlined approach not only simplifies the production process but also enhances design flexibility, allowing for modifications even at advanced stages.

Applications of rapid tooling injection molding are vast and varied. Industries ranging from automotive to consumer electronics benefit from this technology. For instance, manufacturers can quickly produce prototype parts for testing, enabling them to refine designs before committing to mass production. Additionally, rapid tooling is ideal for short-run production, where traditional methods may be inefficient or economically unfeasible.

In conclusion, rapid tooling injection molding is revolutionizing the way products are developed and brought to market. It offers significant advantages in speed, cost, and flexibility, making it an essential technique for modern manufacturers. By leveraging this innovative approach, businesses can stay competitive in an ever-evolving landscape, fulfilling customer demands with agility and precision. Embracing rapid tooling can lead to enhanced product quality and increased market responsiveness, ultimately driving success in the manufacturing sector.

The core advantage of rapid tooling injection molding lies in its speed. Traditional injection molding requires extensive lead times for mold creation, often taking weeks or even months. However, rapid tooling can drastically shorten this period to just a few days or weeks, depending on the complexity of the design. This acceleration allows companies to respond to market demands more swiftly, aligning production schedules with consumer needs and trends.

Another vital aspect of rapid tooling is its cost efficiency. While traditional mold-making techniques can be prohibitively expensive, especially for small production runs, rapid tooling allows manufacturers to lower their upfront investment. The use of materials such as aluminum or 3D printed components for molds significantly reduces costs without sacrificing quality. This makes it an attractive option for businesses that need to test new products or enter new markets without committing to large-scale production.

The process of rapid tooling injection molding generally involves several steps. Initially, a digital model of the part is created using CAD software. Once the design is finalized, the mold is produced using techniques like CNC machining or additive manufacturing. After the mold is ready, it is installed in an injection molding machine, where melted plastic is injected into the mold cavity to form the desired shape. This streamlined approach not only simplifies the production process but also enhances design flexibility, allowing for modifications even at advanced stages.

Applications of rapid tooling injection molding are vast and varied. Industries ranging from automotive to consumer electronics benefit from this technology. For instance, manufacturers can quickly produce prototype parts for testing, enabling them to refine designs before committing to mass production. Additionally, rapid tooling is ideal for short-run production, where traditional methods may be inefficient or economically unfeasible.

In conclusion, rapid tooling injection molding is revolutionizing the way products are developed and brought to market. It offers significant advantages in speed, cost, and flexibility, making it an essential technique for modern manufacturers. By leveraging this innovative approach, businesses can stay competitive in an ever-evolving landscape, fulfilling customer demands with agility and precision. Embracing rapid tooling can lead to enhanced product quality and increased market responsiveness, ultimately driving success in the manufacturing sector.

rapid tooling injection molding

Previous Page

Related news

2024-11-15