Rapid tooling

Keyword:

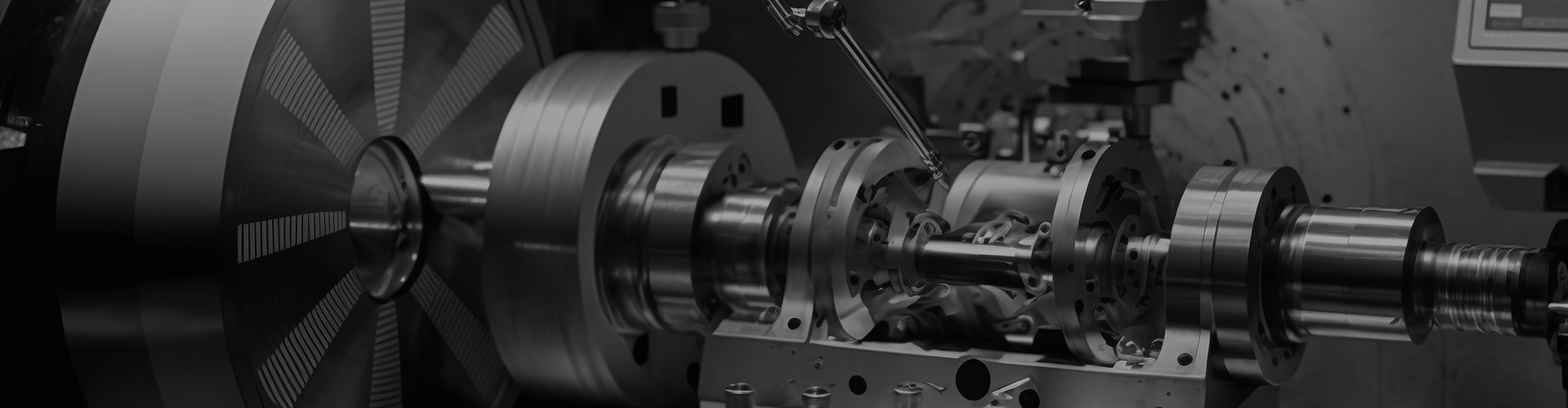

The uniqueness of Wholesale CNC machining parts lies in its high degree of automation, flexible and changeable processing capabilities, wide material adaptability, and excellent processing accuracy. These advantages make CNC machining occupy an irreplaceable position in modern manufacturing

Keyword:

Cheap Precision CNC machining parts

With its high precision, flexibility, and economy, Cheap CNC machining services have adapted to the ever-changing market demands and have shown broad application prospects and potential for sustained growth in the future manufacturing industry

Keyword:

By comprehensively evaluating the supplier's capabilities, clarifying technical requirements, and considering cost and delivery time, you can effectively select the appropriate customized CNC machining service to ensure high-quality machined parts and an excellent service experience.

Keyword:

Prototype CNC machining products

Good price and quality Prototype CNC machining products provide key support for product development by providing high precision, fast turnaround, and material diversity. It enables complex designs and high-quality surface treatments, making it possible to effectively verify and optimize designs before actual production.

Keyword:

CNC machining is an economical process to produce rapid prototypes in China. As the CNC prototyping China factory, we’re good at manufacturing high precision metal machined parts and quality plastic prototypes to serve various industries, such as medical devices, motorcycle, automotive, optical communication, electronics, sporting equipment, injection molding and machinery.

Keyword:

Through these maintenance measures, the performance and accuracy of customized CNC machining part products can be effectively maintained, their service life can be extended, and the stability of processing quality can be ensured

Keyword:

The Advantages and Applications of Rapid Tooling in Manufacturing

Rapid tooling is an innovative manufacturing technique that has gained traction in the field of machining and mold production. This method involves the quick fabrication of tools, molds, and dies using advanced technologies such as 3D printing, CNC machining, and additive manufacturing. The primary goal of rapid tooling is to reduce lead times and costs associated with traditional tooling methods,

Understanding Rapid Tooling: Revolutionizing Manufacturing Processes

Rapid tooling refers to the accelerated process of creating tooling components through advanced manufacturing techniques. In the realm of mechanical hardware processing and mold fabrication, rapid tooling has emerged as a game-changer, significantly reducing lead times and enhancing overall production efficiency. Unlike traditional tooling methods, which can be time-consuming and costly, rapid too

Knowledge of the physical properties of forging die materials

It has good matching of mechanical properties such as tensile strength, yield strength, section shrinkage, elongation, impact toughness and hardness in the range of mold use temperature (room temperature to maximum working temperature).

Keyword:

What are the commonly used materials for molds?

Commonly used materials for molds: T7, T8, T12, 6CrW2Si, 5CrMnMo, Cr12, Cr12MoV. The use of mold DU is different, and the mold material used is different.

Keyword:

According to the different materials molded, the mold can be divided into hardware mold, plastic mold, and its special mold.

Keyword:

Products

News